Kevin KeaneEnvironment, energy and rural affairs correspondent, BBC Scotland

Pathe News

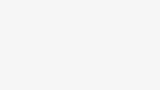

Pathe NewsIt must have been a bizarre sight when a freight ship, equipped with two large rotating towers, made its way under the Forth Bridge a century ago.

The experimental sail technology, on the rotor ship Buckau, was first demonstrated in 1925 on a journey carrying timber from Danzig – now Gdansk, in Poland – to the Scottish port of Grangemouth.

The spinning towers were designed to harness the wind as a way of saving fuel but it didn’t catch on for about 90 years.

Now the pioneering Flettner rotors are being used on at least 35 commercial freight ships to improve fuel efficiency and reduce their impact on the climate.

Hulton Deutsch/Getty Images

Hulton Deutsch/Getty ImagesThe original ship was modified to incorporate the tall spinning towers, which were powered by motors, as a way of saving money on fuel costs.

Experts say the relatively low cost of fossil fuels, like diesel, meant it was unlikely the shipping lines of the 1920s would make back the investment required to install them.

The Great Depression of 1929 was the final nail in the coffin for the design, with orders being cancelled by ship owners.

But modern-day decarbonisation targets mean technologies which can improve fuel efficiency, like this one, are becoming more highly prized in the maritime sector.

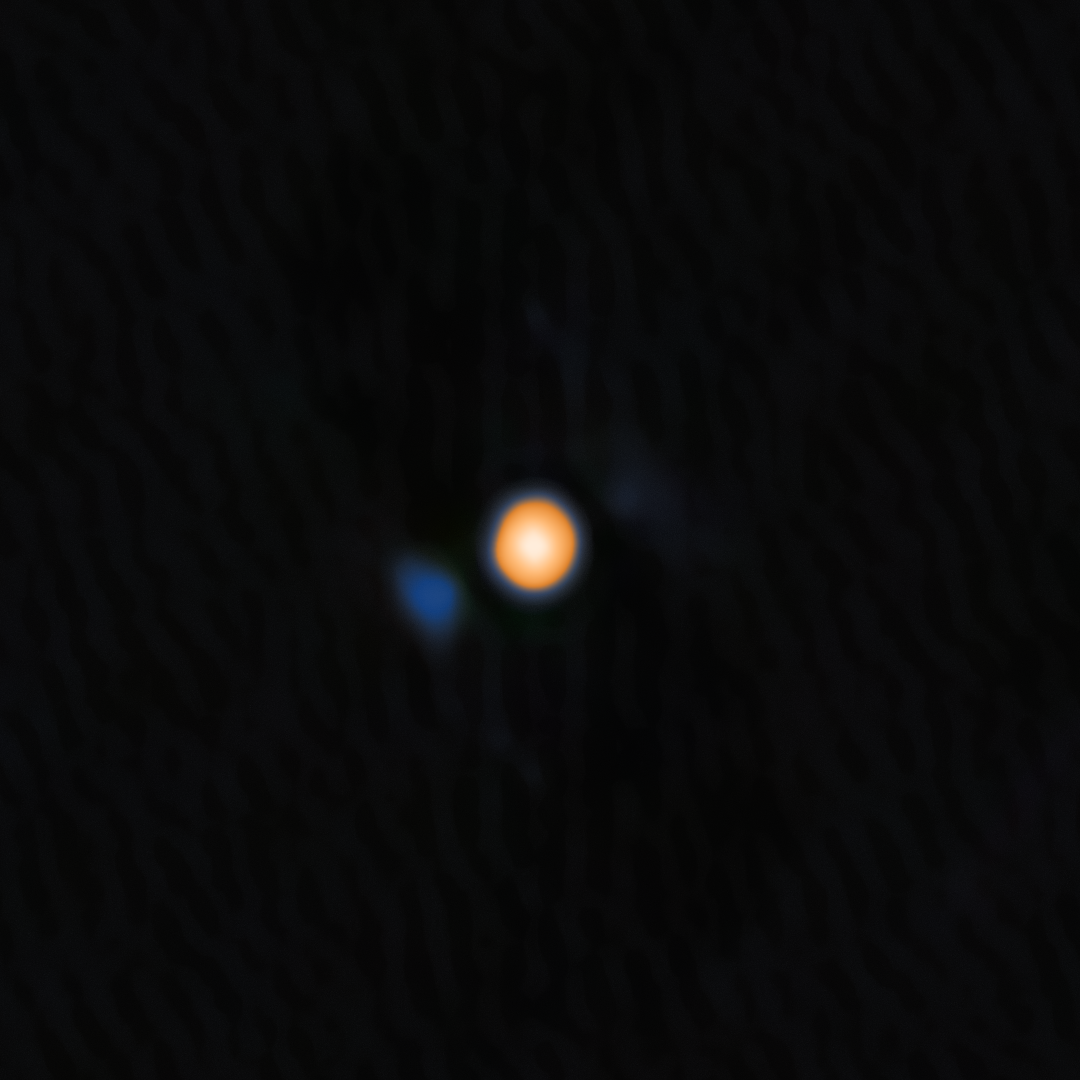

Norsepower

NorsepowerThe technology, known as Flettner rotors, were designed by aeronautical engineers led by the German inventor Anton Flettner.

The towers are powered by motors which effectively redirect the wind to generate forward thrust.

It’s called the Magnus effect and is the same principle which causes a spinning football to bend through the air – especially when kicked by David Beckham.

Operators say it can cut fuel bills by up to 20% as well as reducing planet warming greenhouse gas emissions from burning diesel.

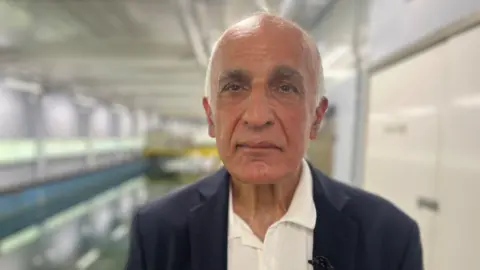

BBC News

BBC NewsModern rotors are even more efficient than the ones on Buckau in 1925 because they are made with lighter composite materials such as carbon fibre.

Prof Mehmet Atlar, an expert in hydrodynamics at Strathclyde University, believes there was a lot of initial interest in the design with an order book starting to grow.

A larger ship was launched, called the Barbara, with a further six waiting to be built.

But by the end of the 1920s, those orders were being cancelled and the design concept was shelved.

He said: “In my opinion, nothing is new.

“The need is the most important thing. The need now is there, therefore the Flettner rotor came back.”

He said that the lighter materials, combined with more effective motors to drive the rotors, mean it’s much more effective than a century ago.

‘Sustainable solution’

The Finnish company Norsepower revived the design when it began exploring fuel efficiency systems for ships more than a decade ago.

It has since built 35 sails, mostly retrofitted, with orders for a further 48.

The company said some ships were even being built “rotor ready”.

Chief executive Heikki Pöntynen said: “I would say that this will become a very common sight.

“We can see the market booming and developing very fast.”

He added the lighter materials were important.

But Mr Pöntynen said the use of artificial intelligence, to drive the positioning of the “sails” against the direction of the wind, made it most effective.

He also said the Flettner rotor was a “really sustainable solution” for decarbonising shipping.

The technology can be added to any ship so long as there is sufficient deck space.

That makes it ideal for freight carriers and tankers.

However, Mr Pöntynen added that it would be difficult fitting the rotors to container ships which use every available space.

Source link