By Karan Singh

Tesla is quietly bolstering its vehicle warranty for new vehicles sold under the 2026 model year, adding a new layer of protection for owners in the United States and Canada.

The new warranty documents reveal a “High-Priced Propulsion-Related Part Warranty,” providing an additional 7 years or 70,000 mi (110,000 km) of coverage on certain parts.

This is a clear win for buyers as it offers peace of mind on some of the most critical and costly EV components. Interestingly, this new warranty covers Tesla’s primary vehicles, including the Model S, Model 3, Model X, and Model Y. However, it appears to leave out the Cybertruck.

A New Layer of Protection

Outside of an EV’s main high-voltage battery and drive unit, which have their own 8-year warranties, there are critical components to an EV that this new warranty helps extend.

This new 7-year warranty specifically covers a long list of these expensive parts, protecting owners from potentially costly repairs well after the basic vehicle warranty has expired (50,000 miles or 4 years).

This includes:

-

Power Conversion System (PCS) Assembly

-

PCS Inlet and Outlet Assembly Hoses

-

Ancillary Harness Assembly

-

High Voltage Fast Charge Contactors Assembly

-

High Voltage System Controller

-

Front and Rear Halfshaft Assemblies

-

Front, Right, and Left Electrical Harness Assemblies

-

Supermanifold Assembly

-

Cooling Fan Assembly

-

Radiator

For owners, this new coverage significantly improves the value and long-term security of their purchase, especially with the power control unit (PCS). The PCS ensures your vehicle can both fast charge (L3) and slow charge (L1 or L2). Without it, you’ve effectively got a big brick rather than a battery, and it is one of the components most likely to malfunction if there is an electrical issue.

The Cybertruck?

The exclusion of the Cybertruck from this otherwise welcome news is rather curious. While the reasons aren’t officially stated, there are several possibilities for its absence.

A strong possibility is simply due to the different architecture of the Cybertruck, which relies on 800V for its higher-voltage systems and 48V for its lower-voltage systems. These unique architectures may mean that its components don’t fall under the same classification or structure as Tesla’s, relying on less exotic systems.

Another factor is that the Cybertruck is still in its early stages of production. Tesla may still need to gather more long-term reliability data on its newer parts before extending warranty coverage for those items.

Of course, Tesla may simply not have updated the warranty documents for the Cybertruck yet.

The new warranty is definitely a big bonus for customers purchasing new vehicles under the 2026 model year, and a sign that Tesla is seeing increased reliability in their vehicles. Tesla won’t have made these warranty changes without knowing that an extremely high percentage of the parts involved would outlast the warranty being offered.

Thanks to Mongo for digging through the new warranty documents and letting us know.

By Karan Singh

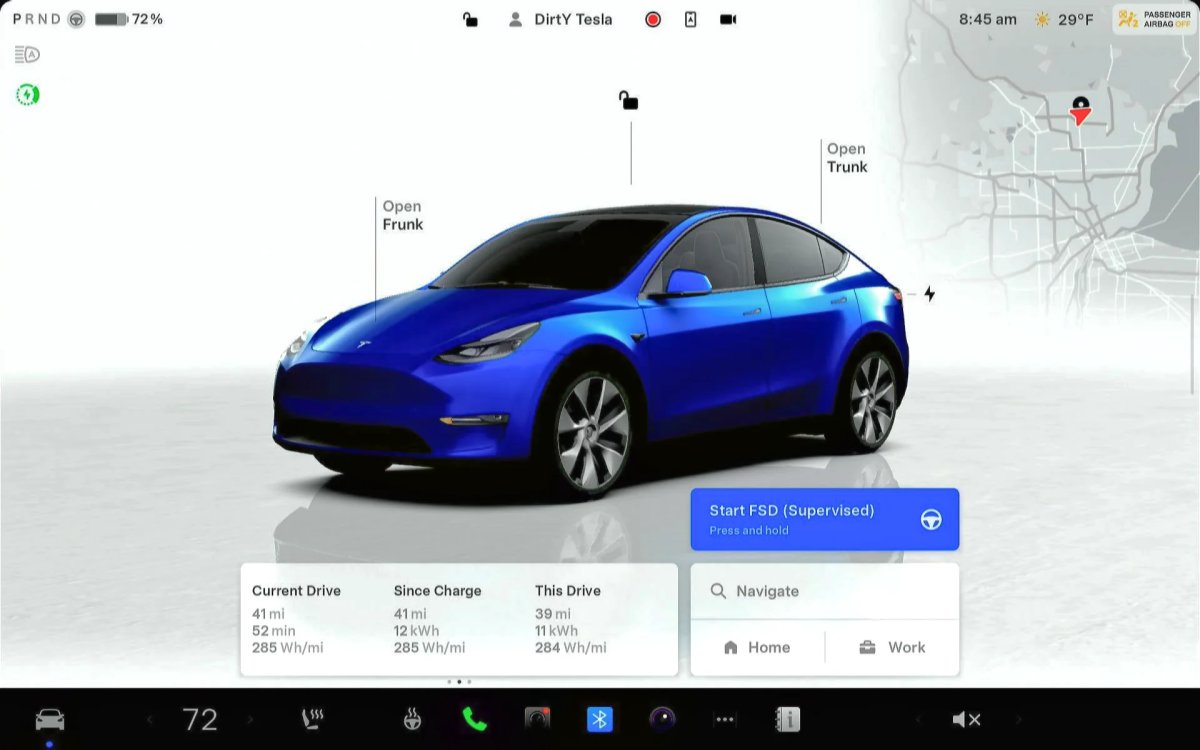

Since the launch of Start FSD from Park earlier this year, owners who use PIN to Drive were faced with an interesting choice. Should they stick with the additional security offered by PIN to Drive, or use the added convenience of the “Start FSD” button?

Unfortunately, the features were not compatible, forcing you to use one or the other. For users of PIN to Drive, the Start FSD button would simply not show up.

Now, in an undocumented change in update 2025.32.3.1, Tesla has finally resolved this conflict and integrated Start FSD from Park, even if you have PIN to Drive enabled.

EASTER EGG DISCOVERED IN TESLA SOFTWARE V2025.32.3.1

To whoever @Tesla heard this feedback and finally remediated the compatibility issue between “PIN to Drive” and “Start FSD (Supervised) from Park, THANK YOU! I always felt like I wasn’t getting the full FSD experience due to… pic.twitter.com/6ah68gnKDD

— Dan Burkland (@DBurkland) September 11, 2025

The Old, Multi-Step Workflow

The on-screen Start FSD button was designed to be the ultimate convenience. Get in your car, put your seatbelt on, and tap one button to get going. However, for owners using the popular PIN-to-Drive feature, it meant additional steps to get FSD started.

The process was a series of manual steps. Previously, a user would have to manually shift into Drive, enter their PIN, and then engage FSD with the stalk or scroll wheel. This completely bypassed the convenience of the Start FSD button and seeing the magic of FSD shifting out of Park and into Drive.

Perfect Integration

The latest update completely overhauls this workflow, and keeps the button’s convenience, along with PIN-to-Drive’s safety and security. The new process is what you’d expect. The Start FSD button now shows up, and PIN to Drive users can tap it like everyone else. Upon tapping the button, the vehicle will prompt you for your PIN before shifting out of park and beginning its journey.

It’s not clear why it took so long to solve this issue with PIN to Drive, but it’s another great reason to have car software updates that fix or add features to vehicles over time.

Tesla continues to listen to feedback and will soon have a tool available for owners to submit feature requests.

By Karan Singh

Despite widespread assumptions about Tesla’s gigacasting technologies, a new report reveals that large structural castings simplify both assembly and collision repair.

For years, a pervasive narrative has shadowed Tesla’s innovative gigacasting technology. While revolutionary for manufacturing efficiency, these massive single-piece castings were widely believed to be a repair nightmare, driving up costs and complexity in the event of a collision.

However, a new report from Thatcham Research directly challenges this assumption, concluding that gigacasting can actually save on vehicle repair expenses. This finding is supported by none other than Wes Morrill, Tesla’s Lead Engineer for the Cybertruck, who stated:

If you simplify the body design with large structural castings, it’s better both for initial assembly and for repair.

The Fears of Gigacastings

The traditional fears surrounding gigacastings centered on the idea that if a section of the casting was damaged, the entire piece would need to be replaced. That means exorbitant labor costs and extensive replacement of parts, small and large. The Thatcham Research study, however, presents a different reality, suggesting that the very design principles that help Tesla streamline production also inherently simplify repairs.

Fewer Parts, Easier Fixes

The core of that myth was based on a misunderstanding of how structural castings are designed and repaired. Conventional vehicle bodies are assemblies of hundreds of stamped metal parts, welded, riveted, and bonded together.

This creates numerous potential failure points and connections between parts, which can cause forces to propagate during a collision, resulting in damage to unrelated areas. Repairing such a structure often involves sectioning, cutting, and rejoining smaller components.

Gigacastings, by contrast, drastically reduce the number of individual parts. Tesla’s approach simplifies the vehicle’s body into a few large, structurally robust segments. This means fewer parts, so less labor, fewer welds, and faster production lines during initial assembly.

In collision repair, with fewer individual components and a more integrated structure, damage can often be more localized, or when a replacement is necessary, it involves fewer parts than repairing a traditional multi-segment body. Tesla uses advanced repair methods, including Gigacast Sectioning to replace only damaged portions of the casting, rather than the entire piece.

To put that into numbers, the study found that partial repairs on a Model Y’s rear gigacast resulted in savings of over £2,000 ($2,700 USD) compared to similar repairs on a Model 3 with a conventional multi-part steel body.

Recasting the Repair Paradigm

The implications of this study are larger than you might think, especially for both the automotive insurance and collision repair industries. Insurers, wary of potential total loss scenarios due to gigacasting damage, will likely look to re-evaluate their models with this new information.

Repair shops, which might have anticipated requiring specialized equipment and training for gigacastings, will likely find the streamlined design, when approached with new techniques, easier and faster to repair than before.

Tesla’s first-principles approach to engineering, often focused on its manufacturing innovations, also extends its benefits throughout the vehicle’s lifespan. While multi-section bodies have been the norm, Tesla is always challenging, breaking, and redefining those rules. Gigacastings are here to stay and becoming more common throughout the automotive industry.

:max_bytes(150000):strip_icc()/GettyImages-2226916507-612bc2981bdf4d069c0ad3ca1ea91088.jpg)