The two complaints I hear most about the $330,000 Ford Mustang GTD are: 1. “That’s barely even a Mustang” and 2. “Why would you spend that much money on a Mustang?” It seems the world has strong opinions on Ford’s 815 horsepower Nürburgring slayer but can’t decide if it’s too little Mustang or too much. I had a chance to drive the car around a track and talk with engineers from Ford and the racecar engineering company they developed the car with, Multimatic, to figure out just how much Mustang the GTD really is. What I learned is very strange, but also fascinating.

The Ford Mustang GTD is meant to represent “the apex of Mustang performance.” That was Ford’s goal on day one — it wasn’t to build the fastest car around the Nürburgring, it was to build the fastest Mustang, using learnings from the company’s GT3 car.

![]()

It’s important to understand this crystal clear goal, because if you don’t, then the GTD will seem like an absolutely preposterous exercise, particularly when you dig into how it was built.

It Starts With A Regular Ford Mustang Body, Then Come The Plasma Cutters

The Ford Mustang GTD starts off as a standard black Ford Mustang body that comes from the Flat Rock, Michigan assembly plant. This seems to be a surprise to many, who think Multimatic — purveyors of the fully carbon fiber Ford GT — essentially built a carbon fiber body from scratch and made it look like a Mustang. I’m not surprised people think this, given statements like this from Ford:

“Mustang GTD shatters every preconceived notion of a supercar,” said Farley, “This is a new approach for us. We didn’t engineer a road car for the track, we created a race car for the road. Mustang GTD takes racing technology from our MustangGT3 race car, wraps it in a carbon fiber Mustang body and unleashes it for the street.”

The truth is that the Ford Mustang GTD doesn’t really have a “carbon fiber… body,” per se. Most of its structure is steel and identical to that of a run-of-the-mill $33,000 Ford Mustang EcoBoost. But that’s the most normal thing about the Mustang GTD, because as soon as the Mustang body-in-white (the basic body structure) gets to Multimatic, out come the plasma cutters.

To meet Ford’s performance goals, with the “North Star” being a sub-7 minute Nürburgring time, Multimatic (which is headquartered in Canada, but which also has lots of engineering operations in Germany) and Ford had a bunch of levers they could pull — crank up power, reduce weight, optimize aerodynamics, optimize suspension design, etc. “You’ve got this multivariate equation that you’re always trying to balance,” an engineer on the team told me, saying the Porsche 911 GT3 RS was the main competitor, though that’s a smaller and lighter car with different constraints.

When I asked about the GTD’s engineering constraints associated with trying to be a Mustang, Ford unsurprisingly didn’t get too much into it, though clearly size/weight are big ones. Ford did tell me the entire point of GTD is to show the capability of their pony — to draw a line between racing and road cars and above all: to elevate the Mustang. That means creating a halo car, and it means giving Ford engineers experience with tech that could trickle down to other road cars. When I asked about an example, GTD Program Manager Todd Valentine mentioned that the GTD ditched the regular Mustang’s MacPherson strut front suspension, and that “We now have a reference” for a multilink setup. Take that for what you will.

In order to accomplish this mission of building the ultimate Mustang that can lap the Nürburgring in under 7 minutes, Ford and Multimatic had to crank up the track width and install absolutely enormous tires. The 345mm-wide Michelin Pilot Sport Cup 2Rs in the back look like rolling pins, and the 325s up front may literally be the widest production car tire ever, tied with the Lamborghini LM002, of which fewer than 350 were ever made (Ford will likely sell over 1,000 GTDs over the next two years).

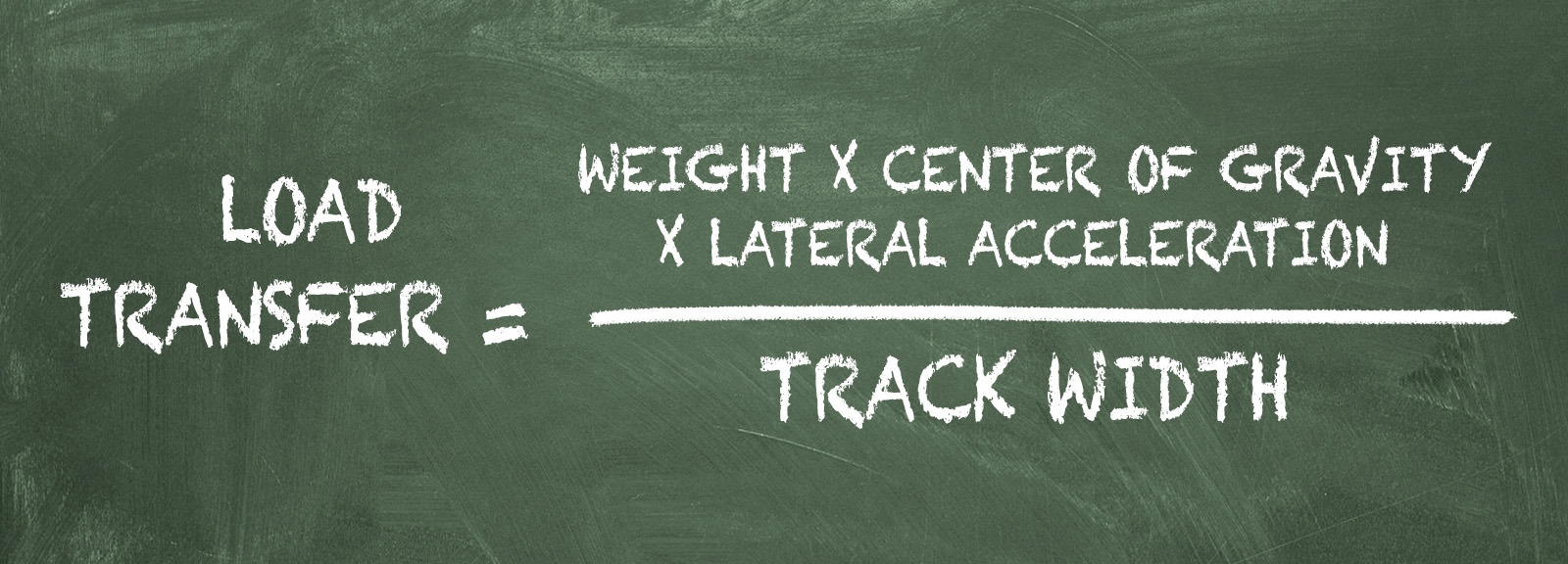

The grippy, wide tires are of course a huge enabler for improving track performance, though the track width itself is huge, too. A wider track yields less load transfer, as the equation below shows that the two are inversely proportional:

Load transfer is important because, even if you design a car that corners perfectly flat, loading up the inside tires way more than the outside tires in a corner is a disadvantage over trying to reduce load transfer and having all four tires more evenly loaded. This is the case because of a concept called Tire-Load Sensitivity, which I described in an old Jalopnik article:

Reducing load transfer can improve overall grip because of a concept called tire load sensitivity. In essence, this term describes the fact that the coefficient of friction between a rubber tire and pavement actually decreases with load, or normal force, at a given slip angle—this is an inherent property of rubber.

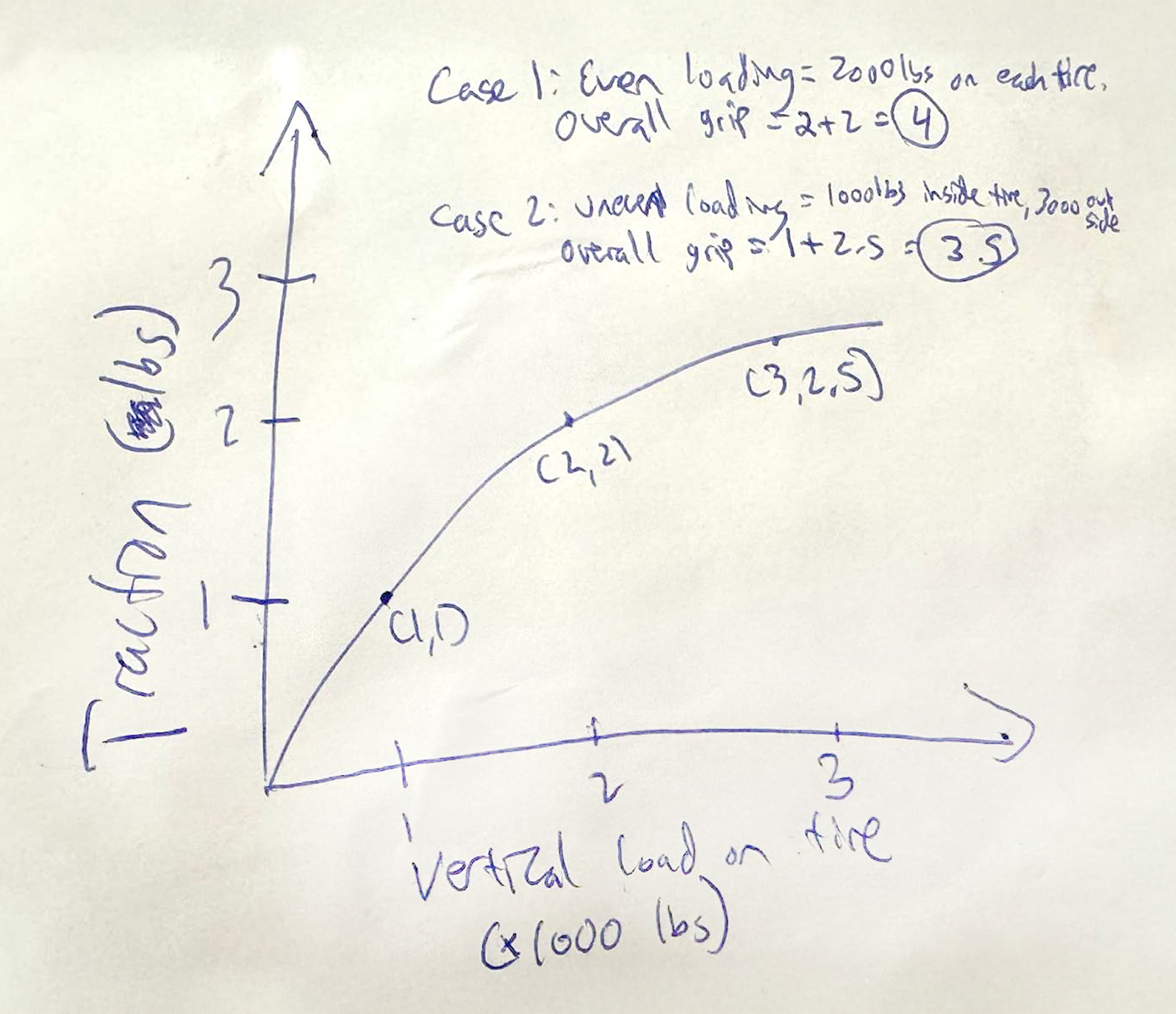

A tire’s overall grip doesn’t decrease with vertical load—it still goes up—but the rate at which grip increases with vertical tire load drops due to that drop in friction coefficient, as is shown in the decreasing slope of the extremely simplified plot below (there’s a similar plot on the website Racing Car Dynamics).

I then give an example of two (rather heavy) cars taking a corner, one with load transfer and one with no load transfer: Case 1 shown below sees 2000 pounds of load on each tire, while case 2 sees 3000 on the outside tire and 1000 on the inside. Notice how having the even loading on the tires yields more grip due to the shape of the tire-load sensitivity curve:

Racecar Dynamics breaks it down, saying:

From analysing [the plot above], it is possible to get important conclusions on the behaviour of a pair of tyres acting parallel to each other, as in the front or rear axles. Under lateral accelerations, there will be a load transfer on the axle from the inside tyre to the outside one. The overall vertical load on the axle will remain the same, yet the total lateral force generated by the axle will be smaller than if no lateral load transfer had occurred.

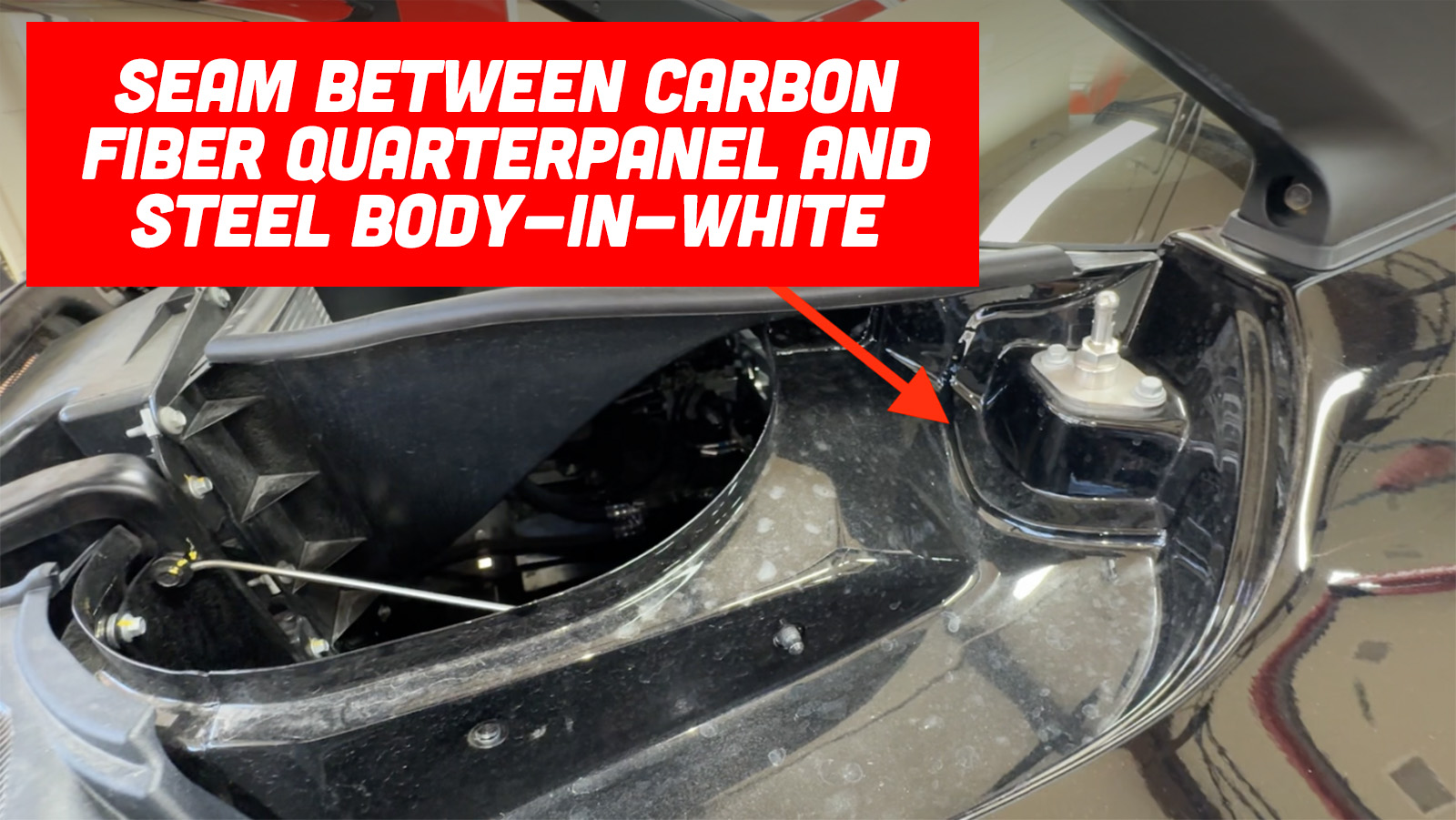

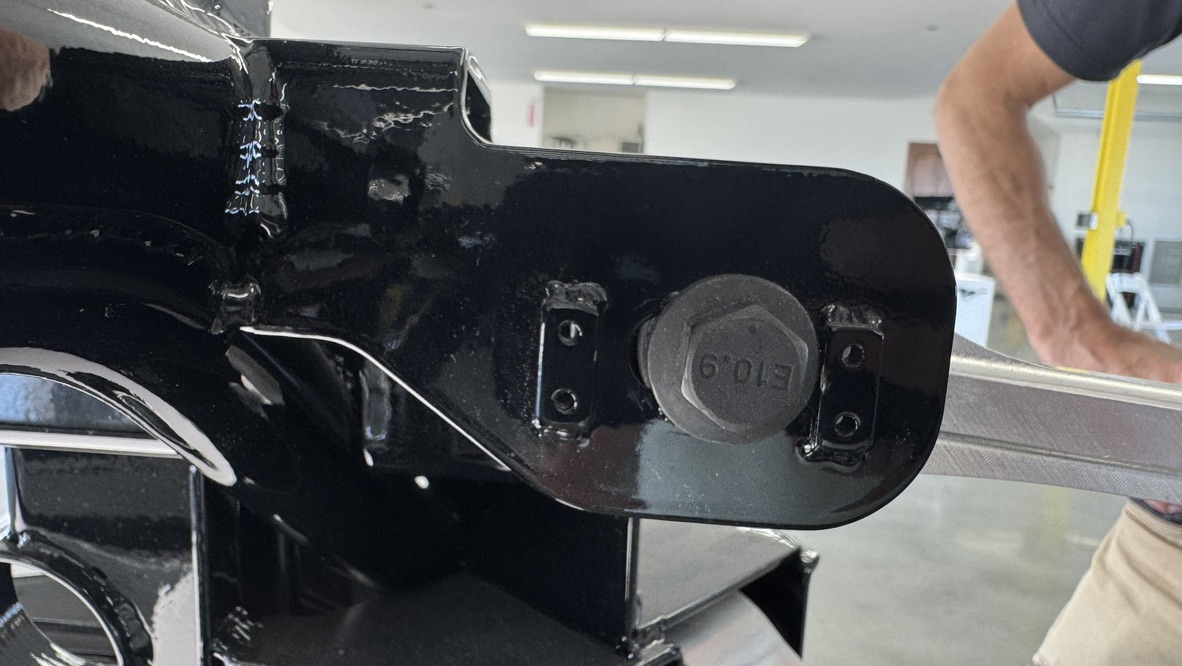

Fitting that wide track and those huge tires in the small space between the standard Mustang’s body structure and the outer sheetmetal wasn’t possible, so Multimatic installed new carbon fiber front fenders and, instead of just tacking on huge fender flares in the back, it sliced off both rear quarter panels with a plasma cutters, replacing them with giant carbon fiber quarterpanels that “shingle” over top of the existing steel. Here’s the seam in the door jamb:

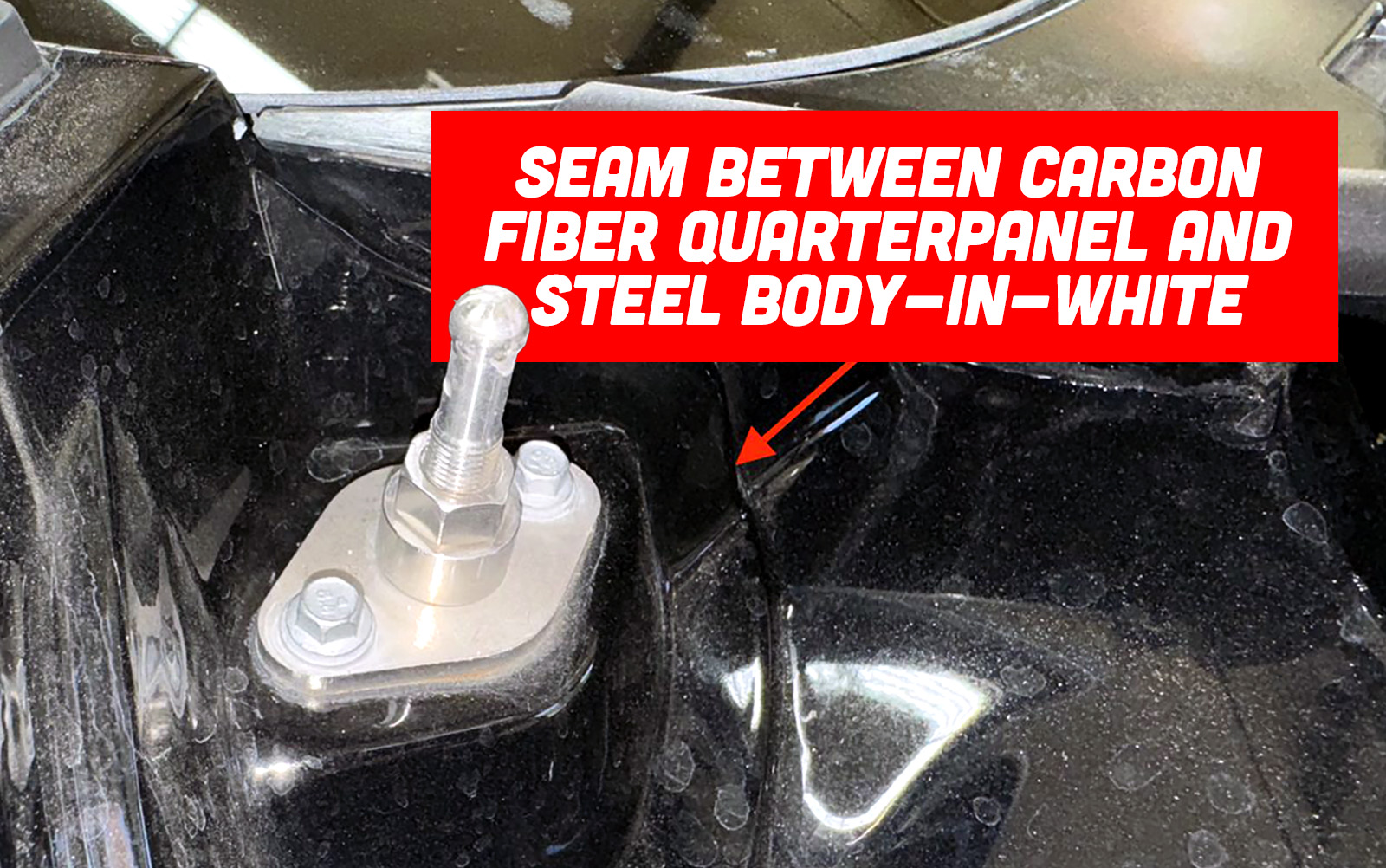

And here you can see the seam between the new carbon fiber quarter panels and the body structure underneath where the trunk lid on a non-GTD Mustang would normally be (the GTD gets a “tech panel” instead of a trunk lid):

The prettiest seam is of course the Class-A surface that one can see from the outside — the roof seam:

In addition to the rear quarter panels, the standard Mustang’s body-in-white also had its trunk floor plasma-cut out to accommodate the Ford Mustang GTD’s eight-speed dual-clutch transaxle (which we’ll look at in a moment) and the car’s all-new rear pushrod suspension.

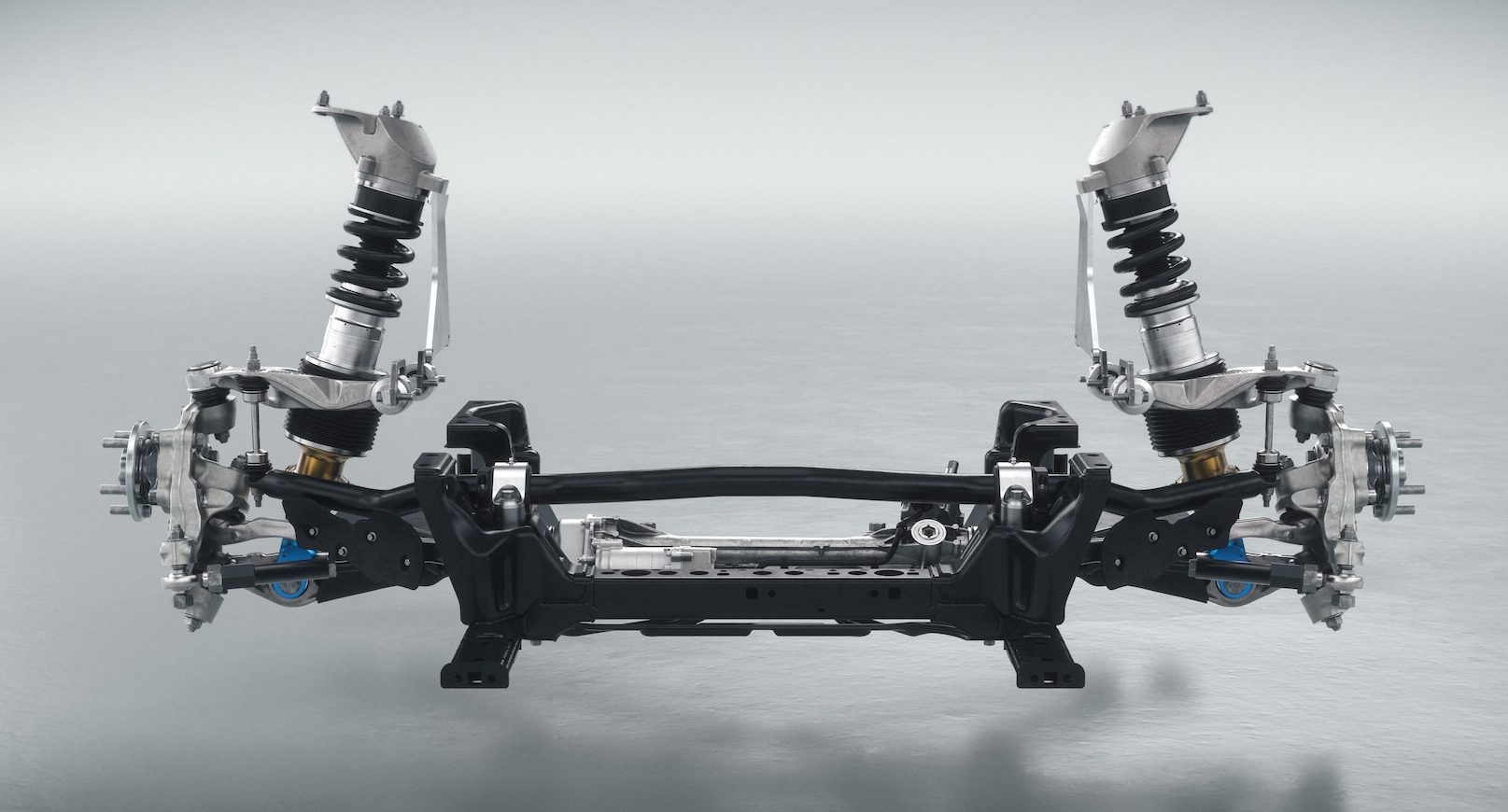

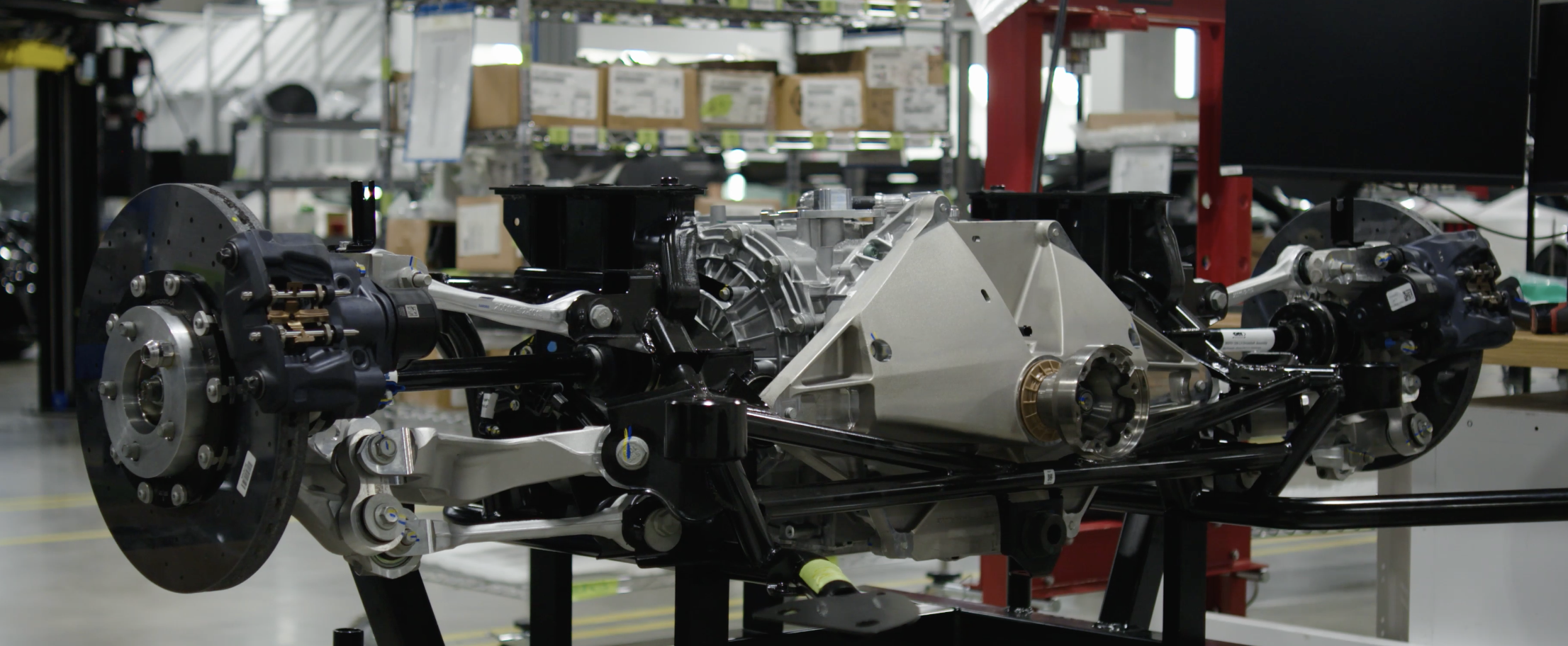

The Pushrod Rear Suspension

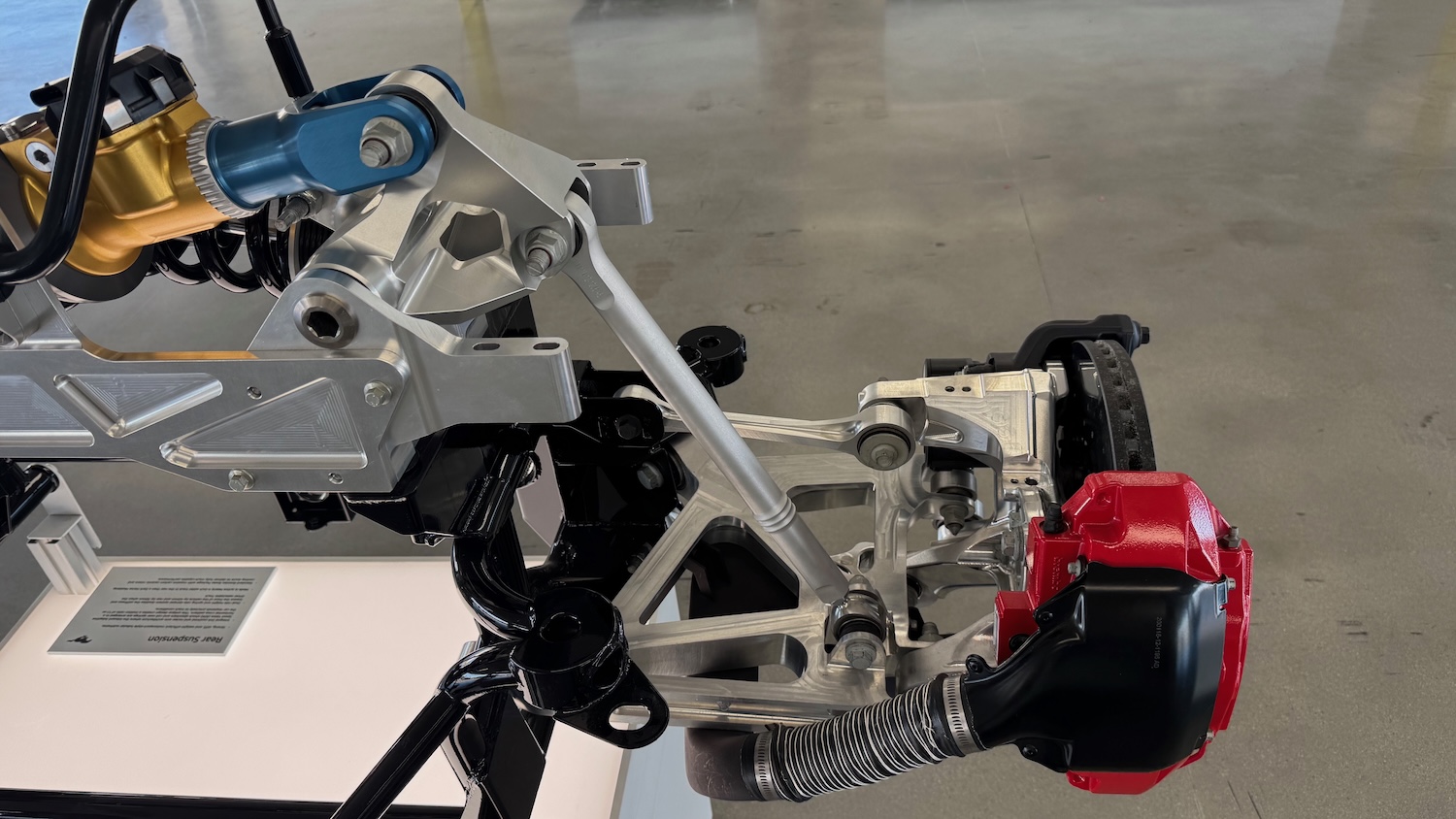

The Ford Mustang GTD’s pièce de résistance is its pushrod rear suspension. That’s what the driver sees in the rearview mirror behind a window that replaces the seat that would be in the standard Mustang. Here’s that window:

The pushrod suspension — as fancy as it looks — was driven largely by a very simple concept: Get more rubber on the ground for better grip. To that end, in order to package the GTD’s 345 millimeter wide rubber rolling pins, not only did the body have to get wider, but the springs and dampers had to move. They could no longer be upright, acting on the body structure.

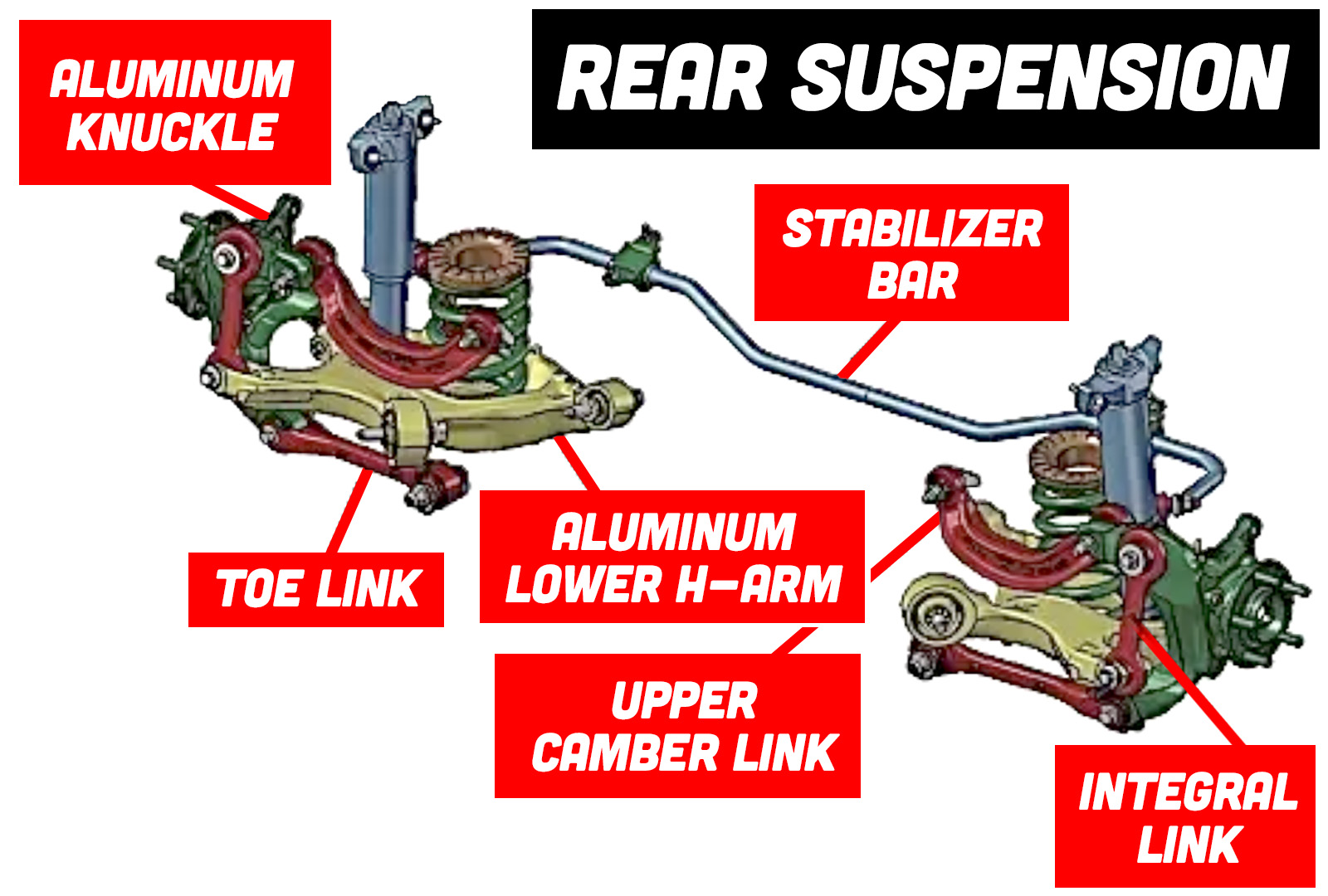

Here you can see a standard Mustang S550 rear suspension; you’ll see that the shocks mount to the suspension’s lower control arms at the bottom and to the body up above via two bolts; the springs, too, mount to the lower control arms down below and push up against spring perches on the body.

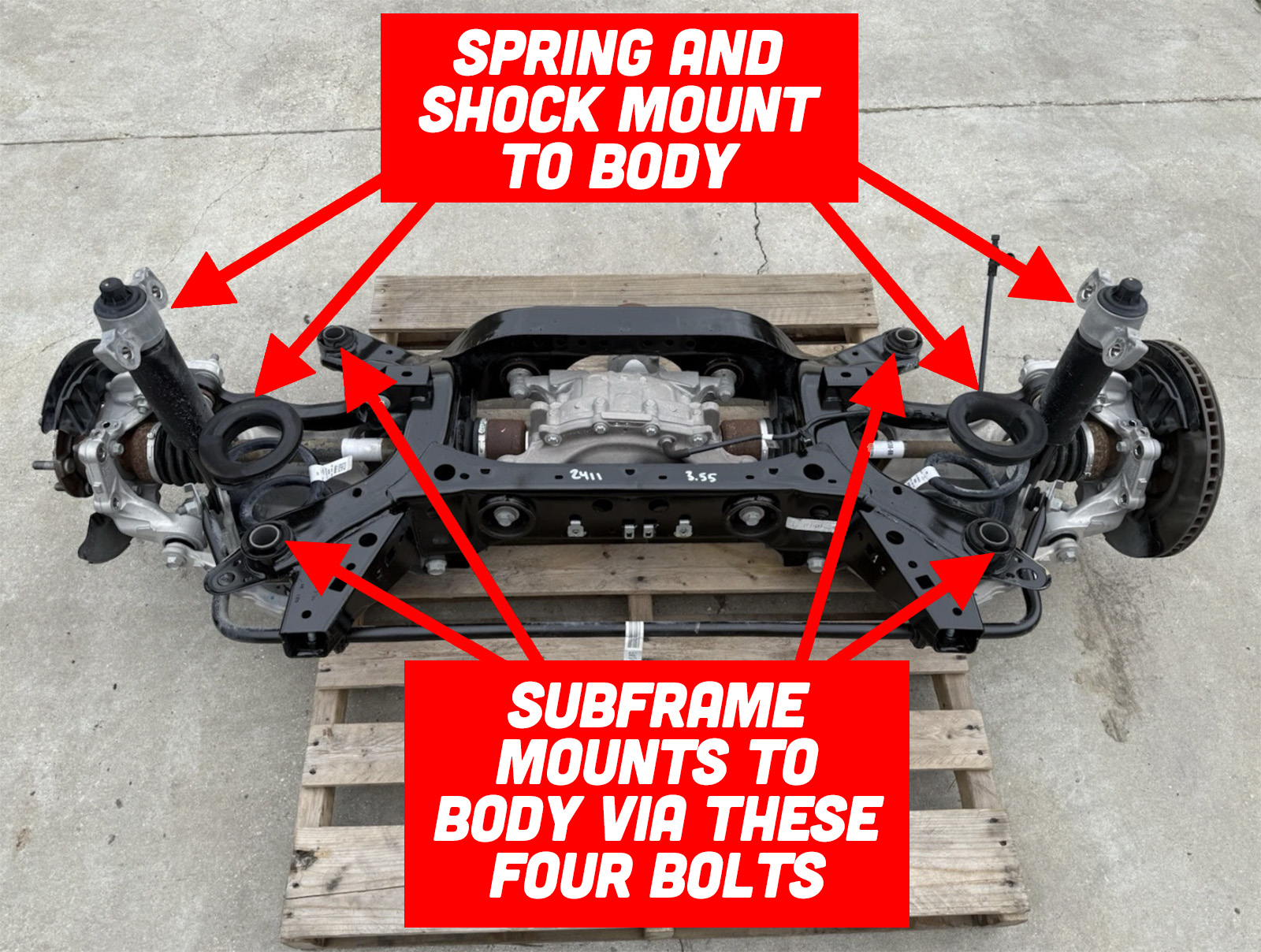

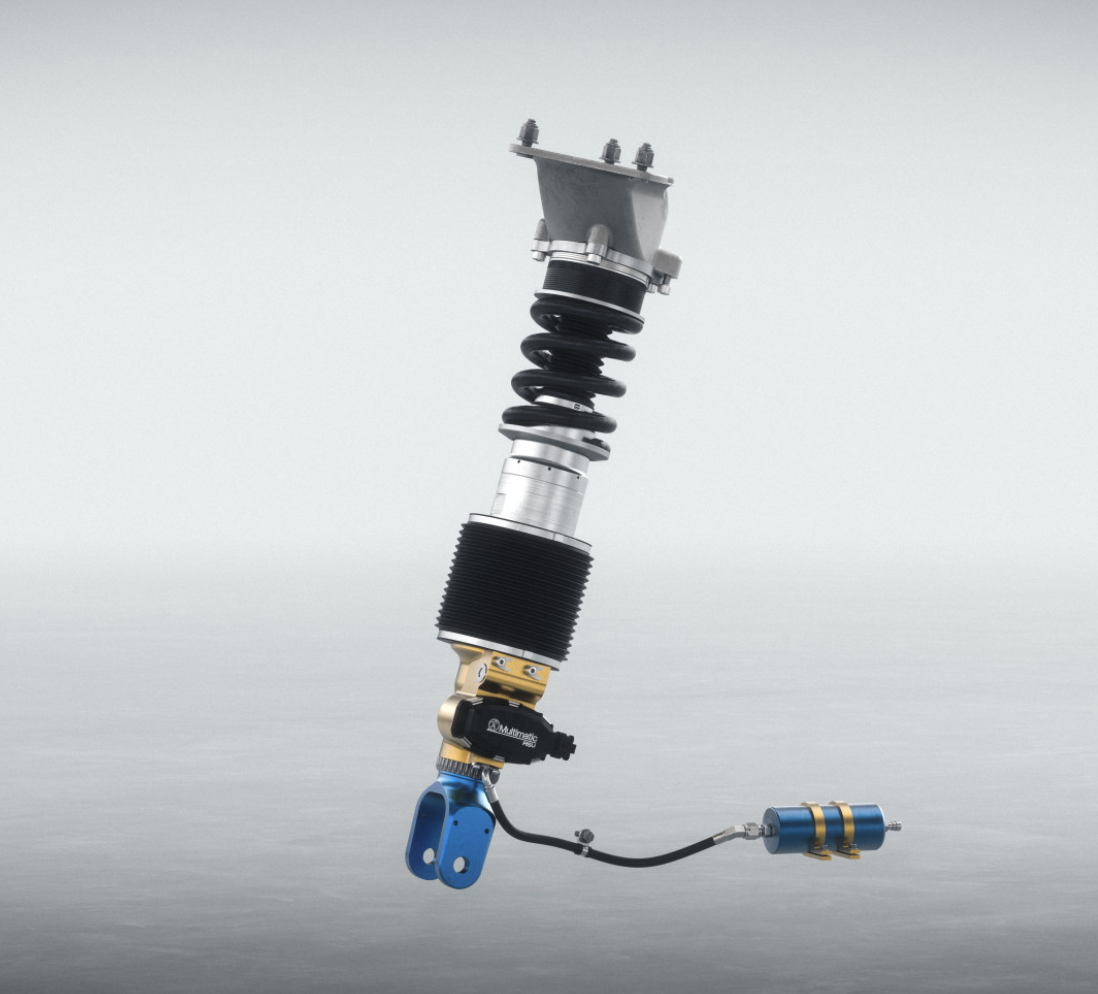

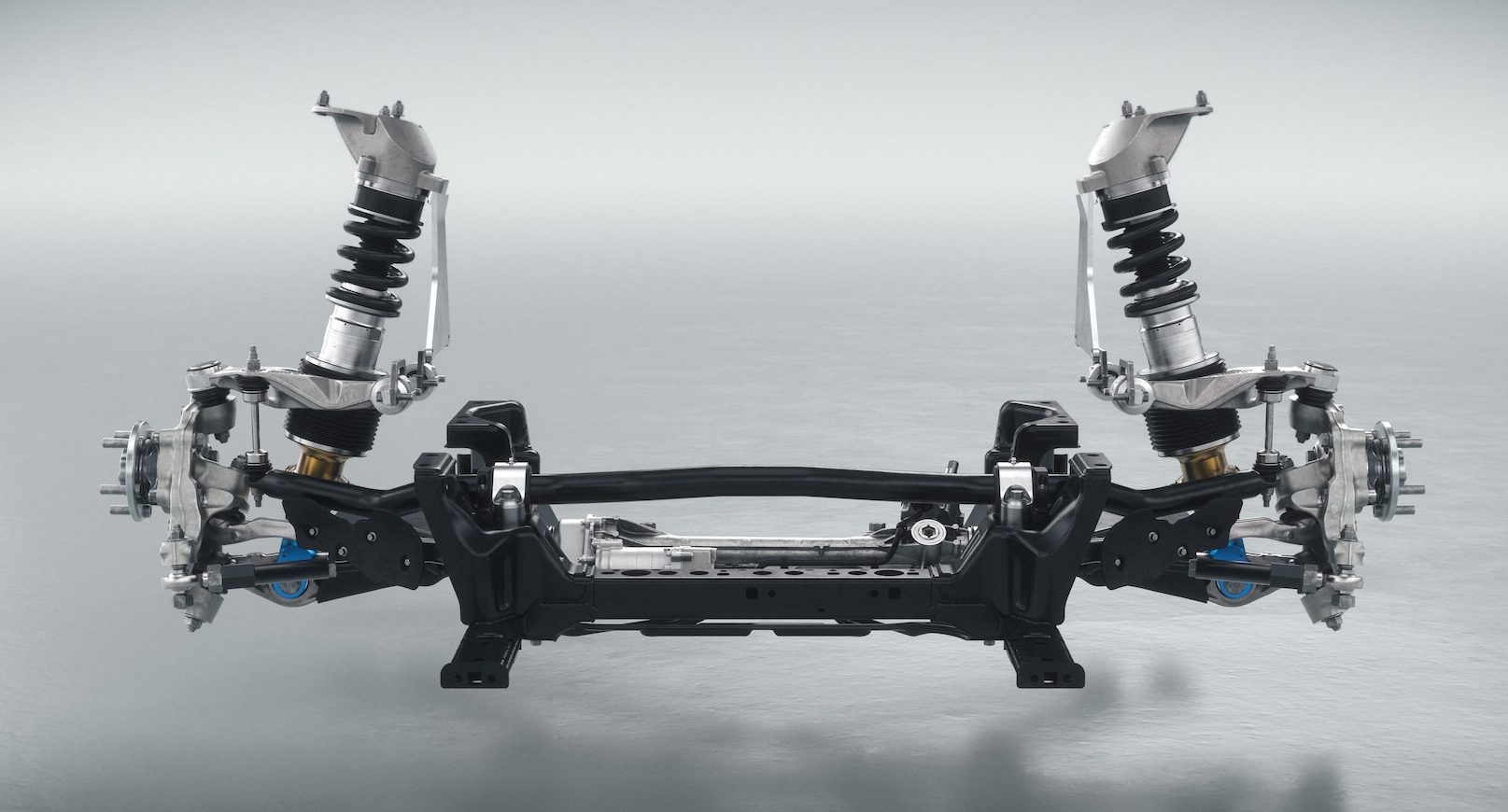

The Mustang GTD uses the same subframe mounting points as a base Mustang (you can see the four bushings in the image above), though aside from that, the suspension is completely different. Instead of having separate springs and dampers, or even upright coilovers, the GTD uses a pushrod-activated inboard coilover design that features Multimatic’s “Adaptive Spool Valve” damping with dual springs.

Each rear wheel gets two springs (technically there’s a small third spring to keep everything tight, but that doesn’t matter for this discussion) in series. One of the springs is stiff, while the other is soft, yielding an overall spring rate that’s actually lower than either. Put the car into track mode, though, and an electrohydraulic valve sends fluid into the gold part of the dampers shown below in such a way that it causes the portion of the damper that would normally telescope with the motion of the soft spring to “bottom out.” With that soft spring locked, the stiff spring is doing all the work, yielding a firmer ride and an overall vehicle ride height that has dropped 40 mm.

Here you can see how those Adaptive Spool Valves function:

It’s a fascinating, and yet remarkably simple system — and a beautiful one. Many of the components that the springs/dampers fasten to are made of billet aluminum, and even the tiny sway bar — skinny, but stiff due to its short length — looks nice.

Notice how that pushrod that connects the beautiful lower control arm to the bellcrank (which attaches to the ASV damper, yielding a 1:1 motion ratio between the wheel’s vertical displacement and the damper displacement) is so thin. This, and particularly not needing to try to package those big fancy springs/dampers upright using the factory body spring/damper provisions, means there’s loads of room for those gigantic, grippy 345-section tires.

Above, you can see the camber link up top, the toe link below, the lower control arm as well, which is connected to the knuckle via an “integral link.”

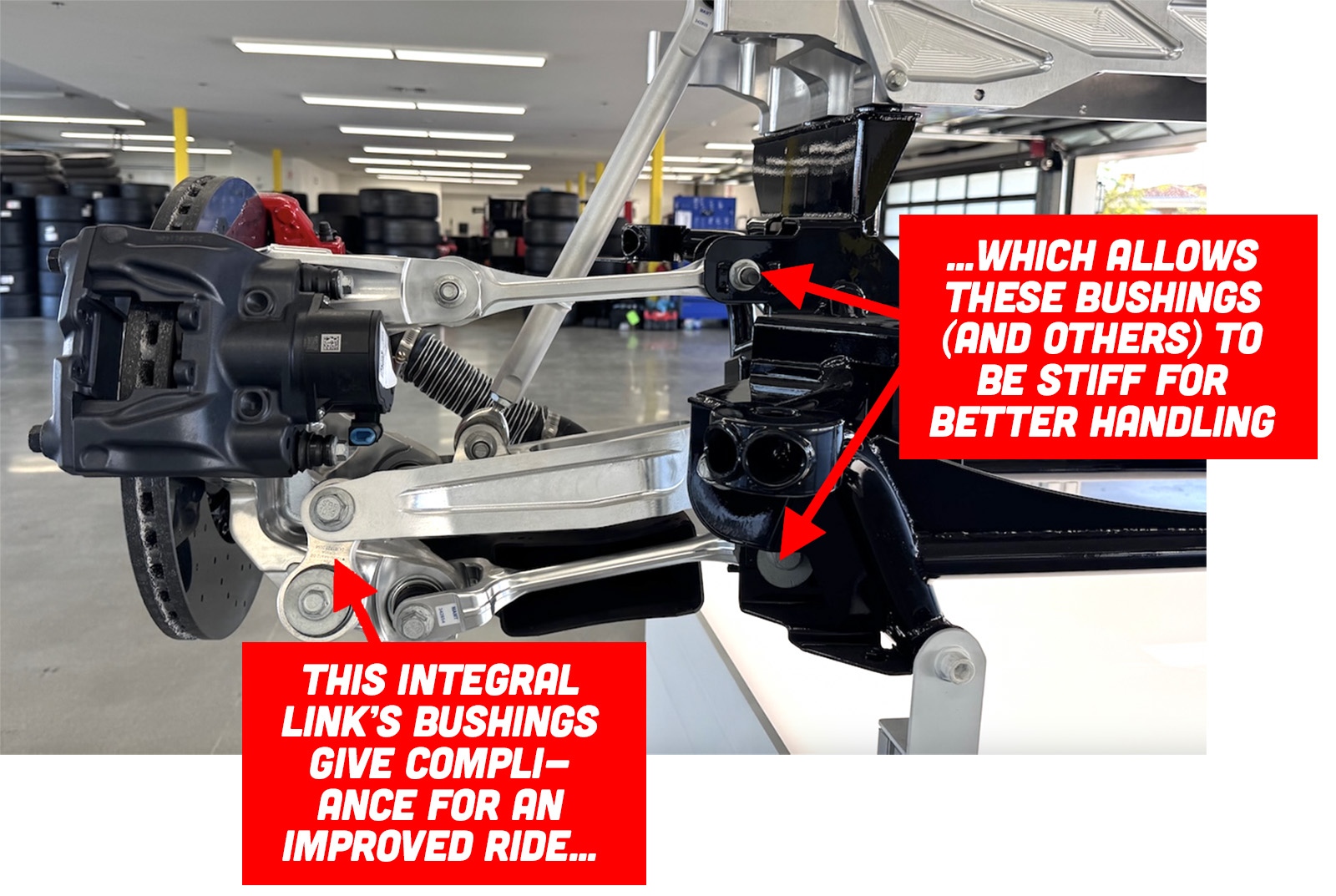

You can read all about the integral link in our story “Why Automakers Still Worship This 30-Year-Old BMW’s Suspension,” as the E39 5 Series is the car that pioneered the design, but I had Multimatic’s Technical Director of Vehicle Development, Murray White, on hand, and he broke it down for me.

He said an integral link is what constrains the wheel’s caster — in other words, it’s what prevents the entire knuckle from rotating towards the front or rear of the car, especially under braking. The two bushings in that integral link can be tuned so that they provide some amount of compliance, meaning if you hit a bump, those bushings will “give” a little. Typically, on a vehicle without an integral link (like a basic double wishbone), it’s the bushings on the subframe side of each control arm that would have to offer that compliance to yield a nice ride. On the GTD, the subframe bushings can be stiff as a rock since the integral link is providing that compliance in the caster direction.

“Allowing the longitudinal …compliance to come from caster rotation rather than allowing the entire suspension to move back on the bushings, means you can run extremely stiff bushings in the lateral links, so you get very high lateral stiffness, still with some recessional compliance, so it’s a better compromise between ride and handling,” White told me.

The Multilink (Short Long Arm) Front Suspension Is Also Extremely Wacky

The Ford Mustang GTD’s rear suspension gets all the love, and you can understand why; it’s beautiful. The billet aluminum, the gorgeous bellcrank (or “rocker”), the slender pushrod — it’s a work of art. Add to that the fact that Ford literally plasma-cut off the rear quarter panels and the trunk floor to fit it, and you’ve definitely got the car’s centerpiece. But the GTD’s front suspension deserves a bit of love, too, because it’s a major departure over the standard Mustang’s front MacPherson Strut setup, and thus required quite a bit of adaptation to the Mustang’s body-in-white.

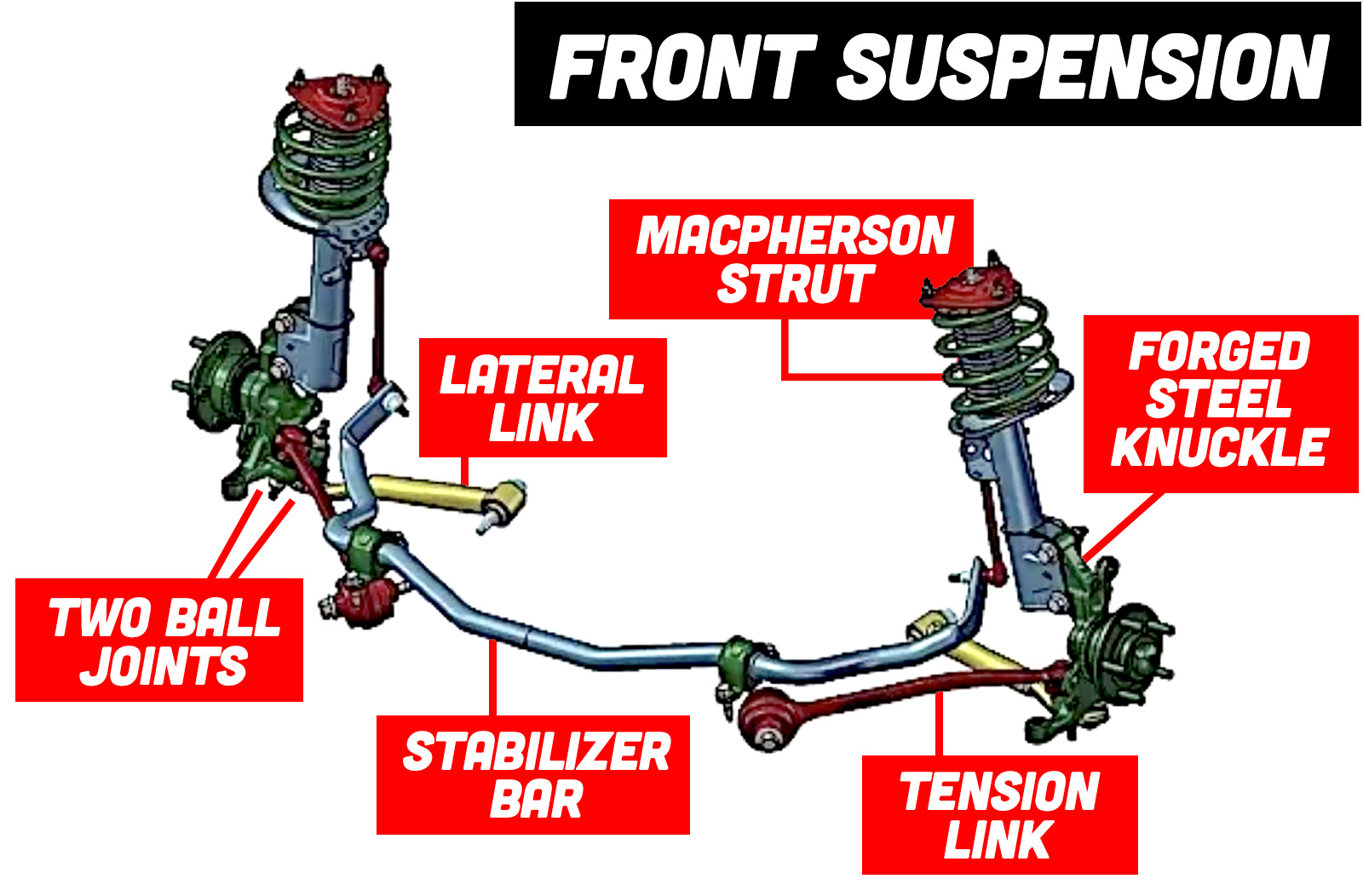

Let’s start by showing the standard Mustang’s front suspension:

It’s a fairly straightforward MacPherson strut design, with the lateral link and tension link essentially making a lower wishbone, and with the strut itself constraining the knuckle’s caster and camber (i.e. making sure the wheel doesn’t tip towards/away from the vehicle, and that it doesn’t rotate backwards/forwards towards/away from the front of the car). As mentioned in Huibert’s “How Suspensions Work” piece, you can think of the strut as a rigid pole that rotates about its own axis (to steer) and that telescopes when hitting bumps.

Of course, the strut isn’t literally rigid, and will flex a bit, which is one of the many reasons the GTD went away from it and towards a multilink design that offers better wheel position control and improved tune-ability. From Ford:

Engineered specifically for the Mustang GTD, the unique multi-link suspension architecture replaces the standard MacPherson strut setup, minimizing friction and improving lateral stiffness and elasto-kinematics, especially in high-G cornering, resulting in more predictability and confidence in front end grip.

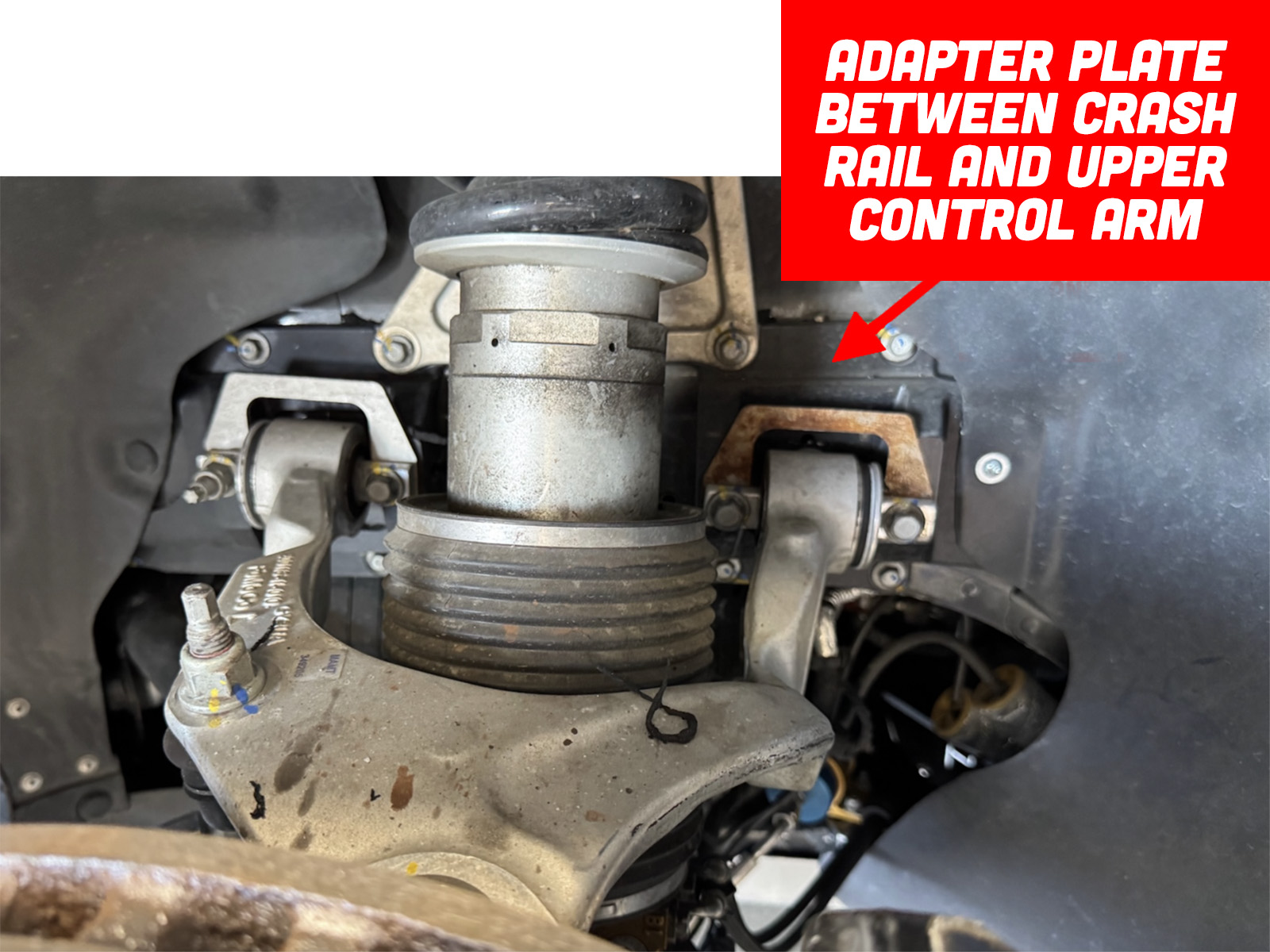

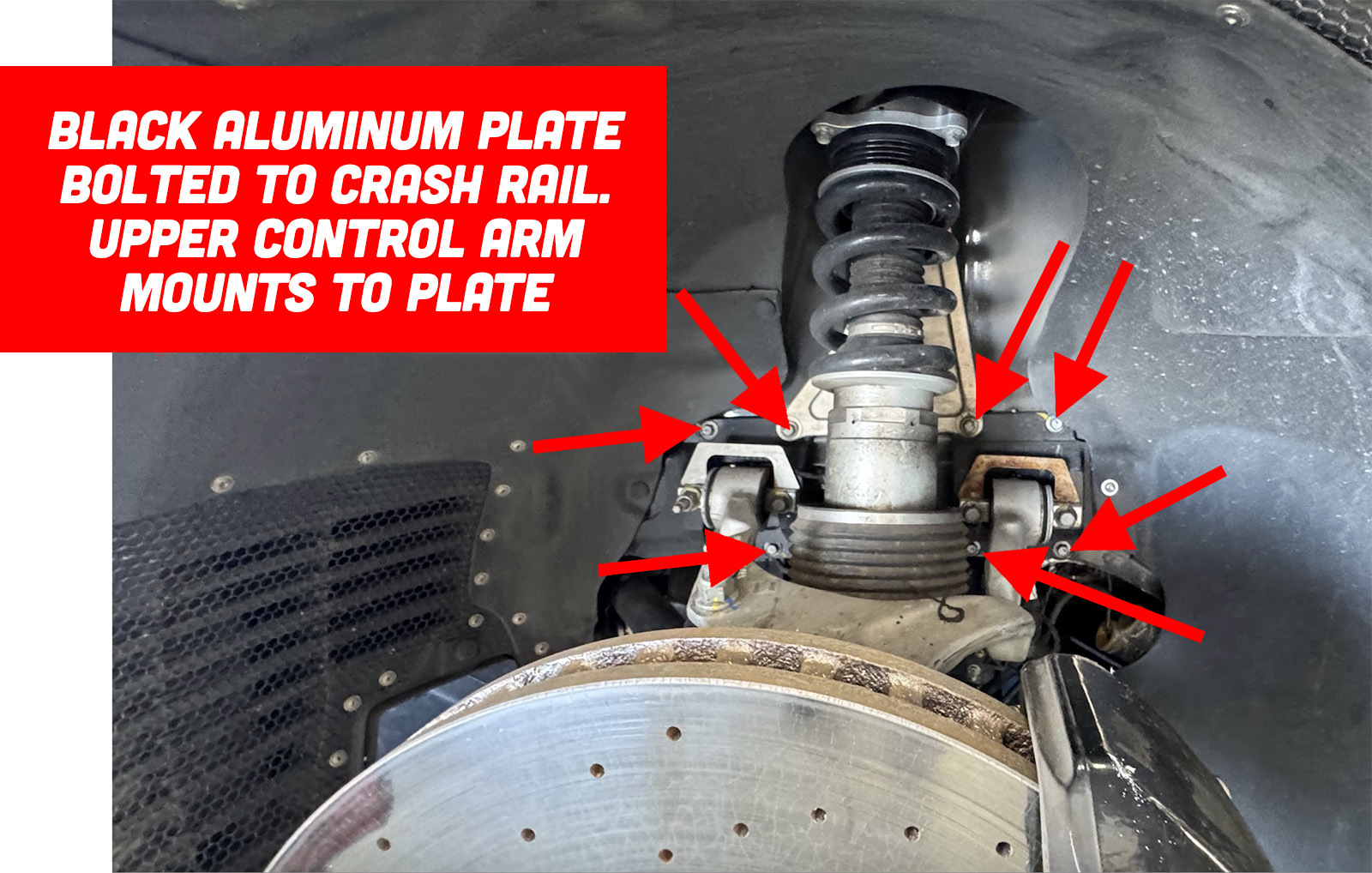

But this redesign wasn’t trivial, as there were no mounts on the Mustang’s body-in-white for an upper control arm. Ford’s solution? They just bolted some onto the Mustang’s front crash rails in the form of a big cast aluminum plate.

Yes, literally bolted:

Here’s another angle; you can see on the left side two bolts that thread through the aluminum plate, through the pinch flange in the crash rail, and into a pair of nuts on the back side:

Interestingly, and likely for packaging reasons to clear those big 325s up front, the strut assembly does not have its axis aligned with the strut tower.

(The front strut assembly, like the rear, features two springs in series, with the softer lower spring able to be hydraulically locked out for track mode. This lowers the ride height and stiffens the ride, though the front strut assembly can also go the other direction, offering lift for speed bumps — the hydraulic lines in the bottom of the image above shows something that looks different than the rear damper assembly, largely because the front has a rubber bellow over the soft spring because the front suspension isn’t sealed off from the environment like the rear is ).

Here you can look at the factory Mustang underhood strut tower, and you can see there’s not a whole lot going on there:

That’s because the upper mount is actually offset from the axis of the damper assembly:

Looking from the bottom, you can see that either Ford painted the top part of the strut-assembly mount black, or there’s a black cover where it meets the strut tower outboard of the top of the strut assembly:

Here’s a good look at the upper damper-assembly mount, which you can see displaces the top of the damper assembly inboard, and which you can see is tied into the upper control arm mounting plate on the crash rail via a shiny vertically-oriented aluminum plate:

Notice that front subframe above; even though the Mustang GTD has a multilink front suspension and not a MacPherson strut like the standard Mustang does, the vehicles share a front K-member (subframe/cradle), though Murray White from Multimatic did point out that the GTD’s lower control arm mounts to it not via bushings like the standard car, but via cross-axis ball joints, which he says provide more lateral stiffness than bushings. Here’s my best attempt at a shot of a cross-axis balljoint (riveting, I know):

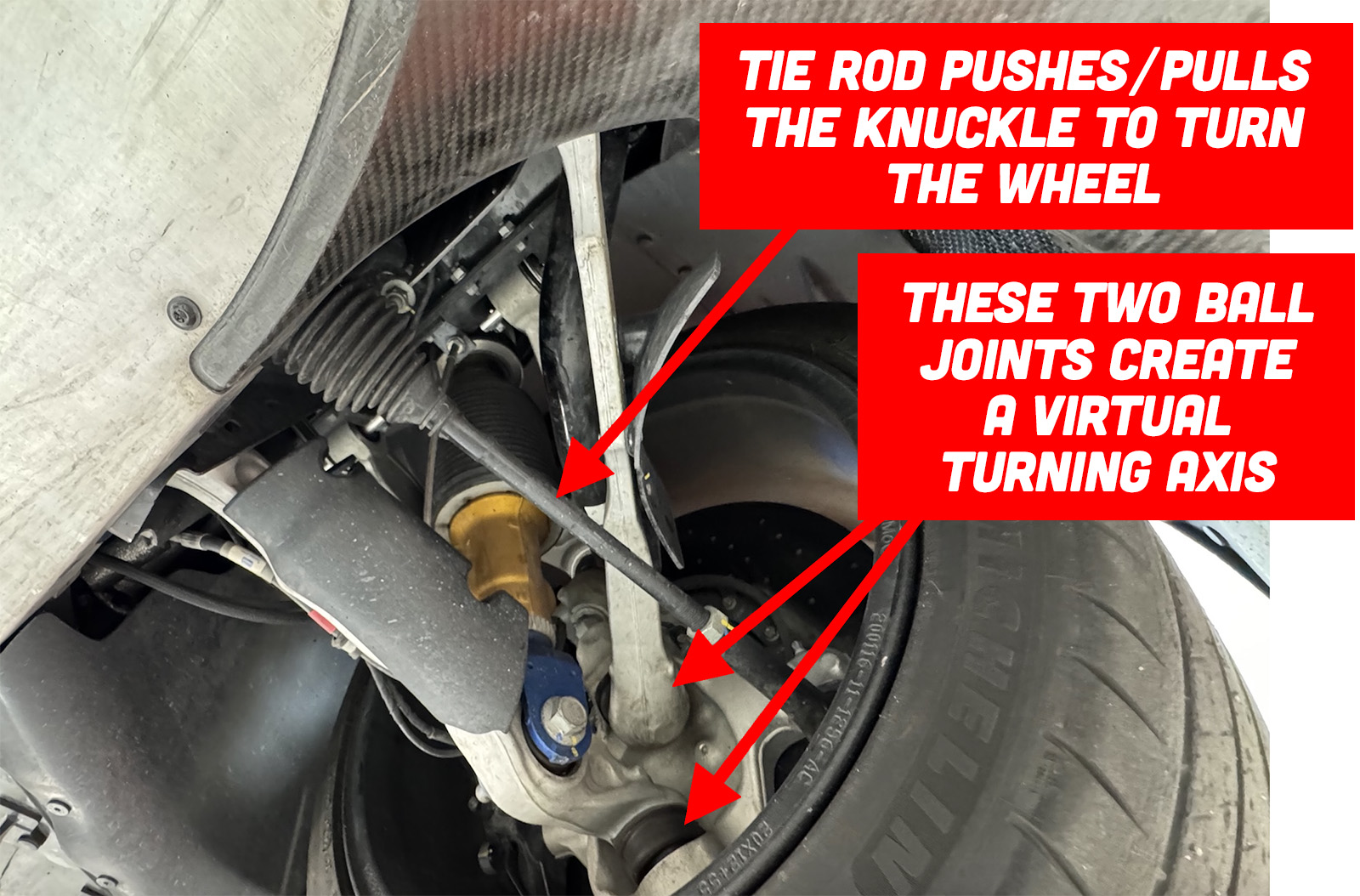

Before I move on, I just want to note that, like the standard car, the Mustang GTD also features a double ball joint front suspension design — something has become increasingly common because of its numerous advantages (like brake packaging); Huibert breaks it all down here in his article; here’s a look at the two ball joints that create the “virtual ball joint” around which the wheel steers.

The Drivetrain

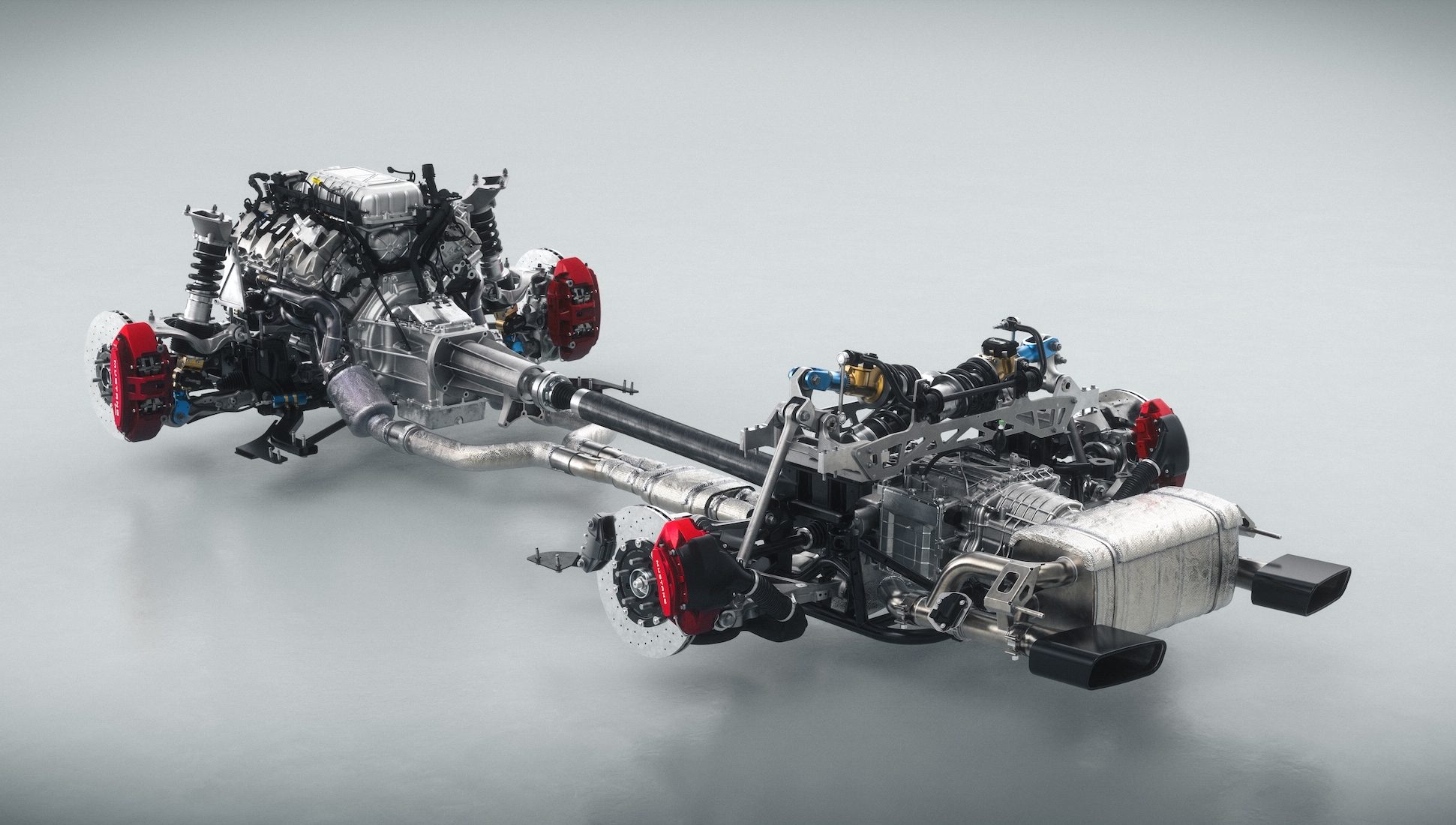

Let’s get into the drivetrain; to do that, we should jump back to that rear suspension, because that shares the subframe with the eight-speed dual clutch transaxle. Here you can see employees mounting this transaxle to the rear suspension subframe:

And here it is all mounted up with the suspension.

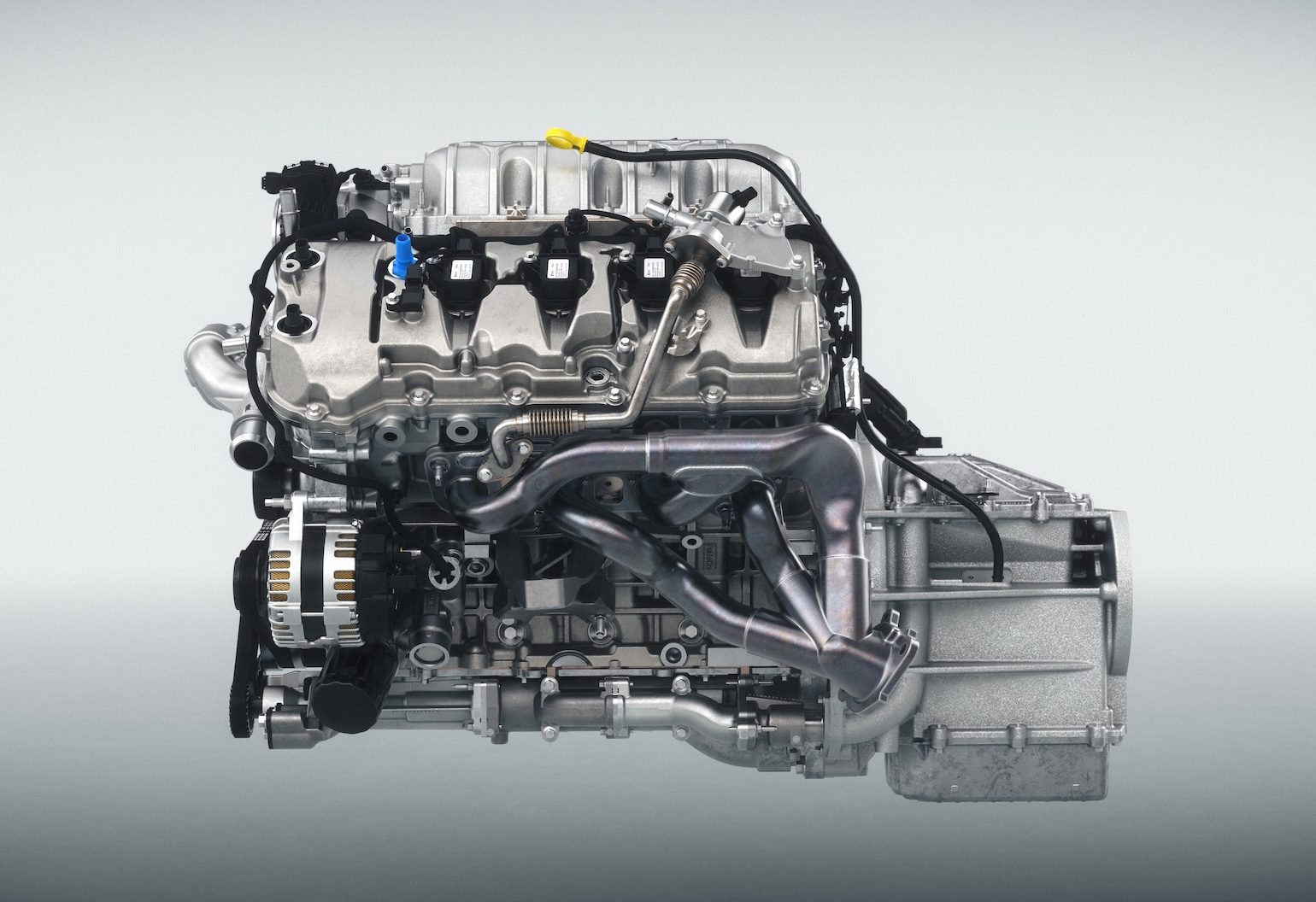

The way this all gets mounted to the car is, the transaxle on the rear subframe gets bolted to a carbon fiber driveshaft (this isn’t a GTD exclusive, but you can imagine how fast that thing rotates given it’s pre-transmission and doesn’t get the gear reduction on a car with a 7000+ RPM redline), which itself is bolted to a Rear Engine Mounting System (REMS), which bolts to the 815 horsepower 5.2-liter supercharged V8:

Here you can see a technician installing the REMS, which features a shaft that goes into… I’m not entirely sure. Is that a dry sump reservoir under an adapter? I don’t know:

The engine comes sitting on the front subframe, which — again — is common with a regular Mustang. And, with the front upper control arms and front strut assemblies mounted to the body, the GTD body (which had everything from its A-pill forward masked off so it stays black for aesthetic reasons) gets lowered onto the front and rear subframes, which are then fastened via just a few giant bolts:

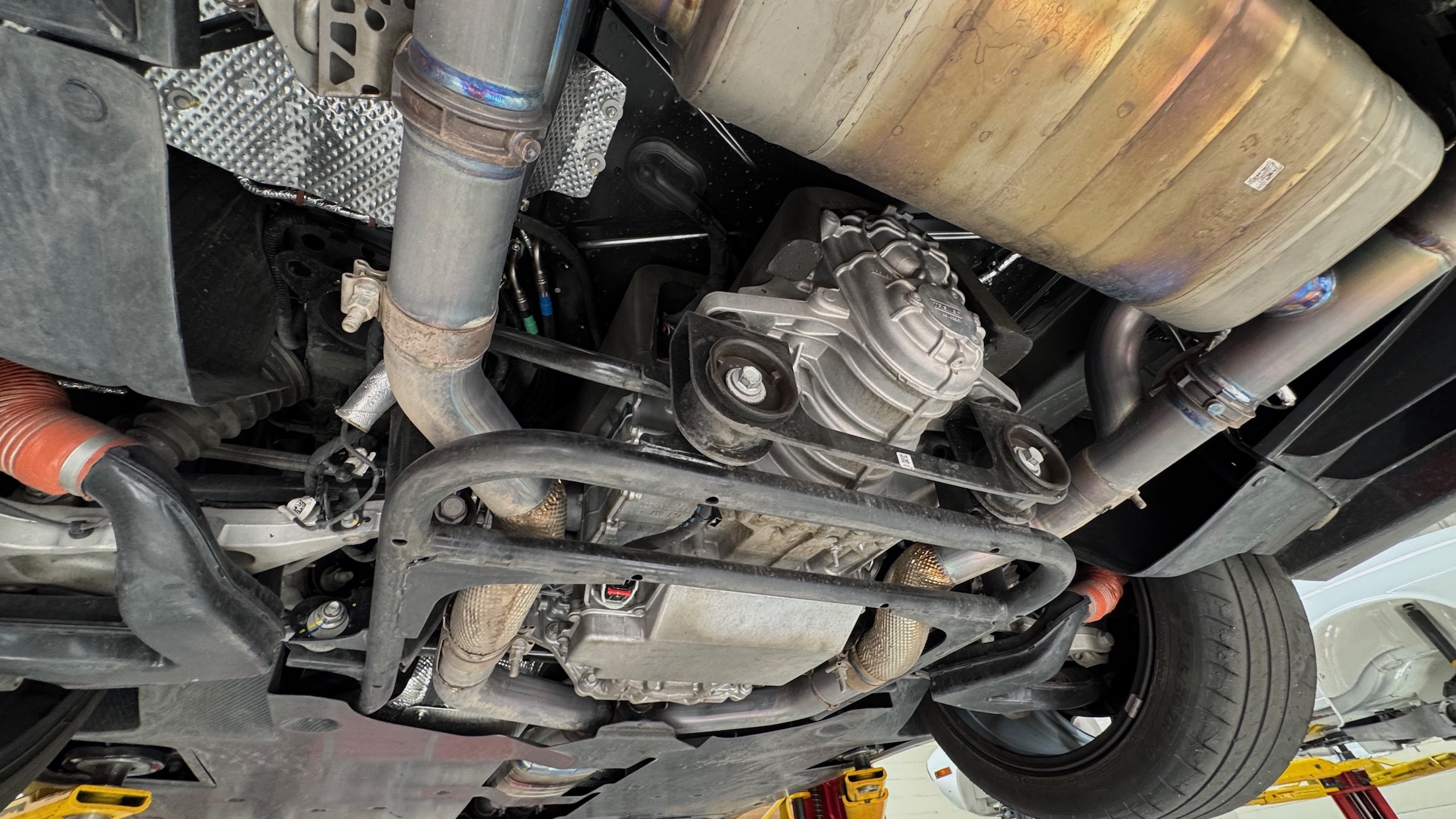

Here’s a look at how that rear subframe looks from underneath; the tubular design is interesting:

The pushrod suspension gets mounted to the top of that subframe, but it goes into the car after the body has been dropped onto that subframe. In the photo below, you’ll see a new acoustic aluminum (two layers of aluminum with some insulator between them) floor to cover the hole Multimatic plasma-cut into the Mustang’s trunk; just underneath the new floor is the transaxle, and as you see above, the pushrod suspension is mounted through the new floor to the subframe below:

A little bit about the transaxle: The TR-9080 dual-clutch transaxle (which is the same model found in the Corvette Stingray) in the rear helps the Mustang GTD achieve a nearly 50:50 weight distribution. It snaps off shifts in a tenth of a second, and as a Tremec engineer told me, it doesn’t pull torque between gears, with the transmission using a hydraulic pump to “speed down” the engine, which actually yields an over-boost function after the shift (this function isn’t in all drive modes, as you could imagine not wanting such a boost while driving around). I can’t say I fully understood all the geekery the Tremec enginerd was imparting on me, but as I’ll describe in my driving impressions, the proof is in the pudding.

Let’s get back to this engine, but only briefly. It’s a 5.2-liter supercharged, cast aluminum, dry sump-equipped V8 that Ford calls a “modified Predator.” It’s got a 9.5:1 compression ratio, four valves per cylinder, and an output of 815 horsepower at 7,400 RPM and 664 lb-ft of torque at 4,800 RPM. Here are a few photos of its glory:

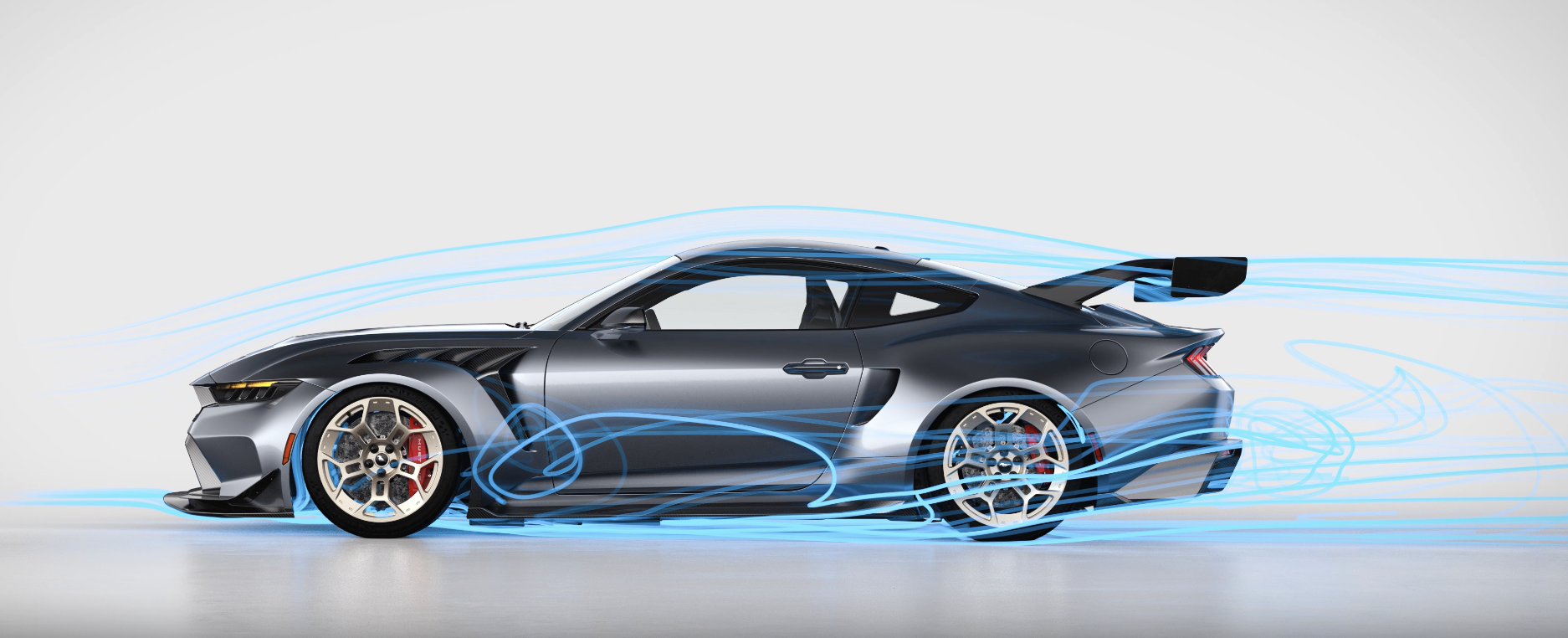

That engine, as you imagine, needs quite a bit of cooling, and the 4,400-pound car, as you also might imagine, needs quite a bit of downforce to get around a track quickly.

Aerodynamics And Cooling

For me to fully cover the Ford Mustang GTD’s aerodynamic features would require me to go back in time and double major in Aerospace engineering instead of minoring in it, and even then, this article would be so long it’d take you all weeks to read.

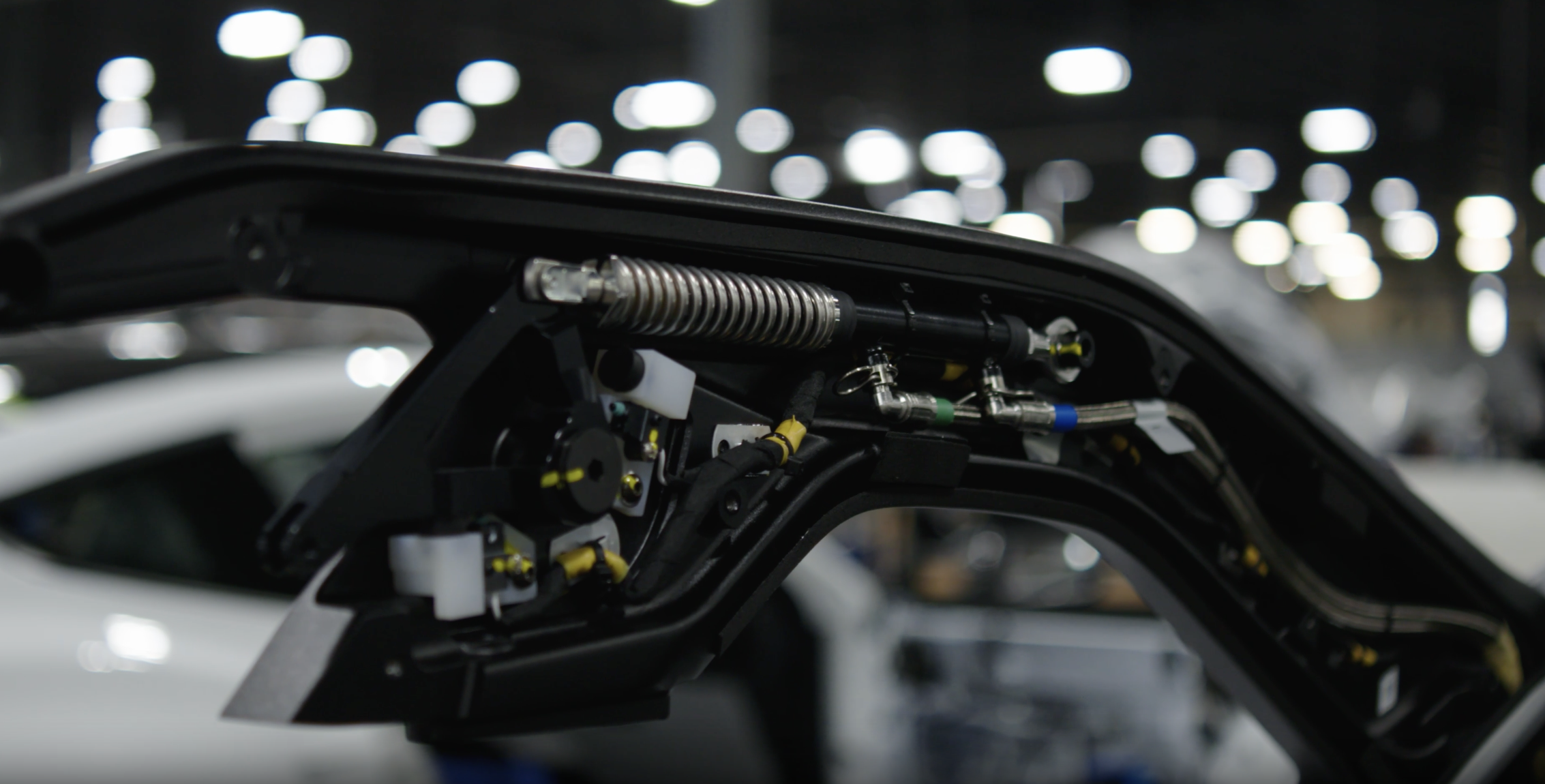

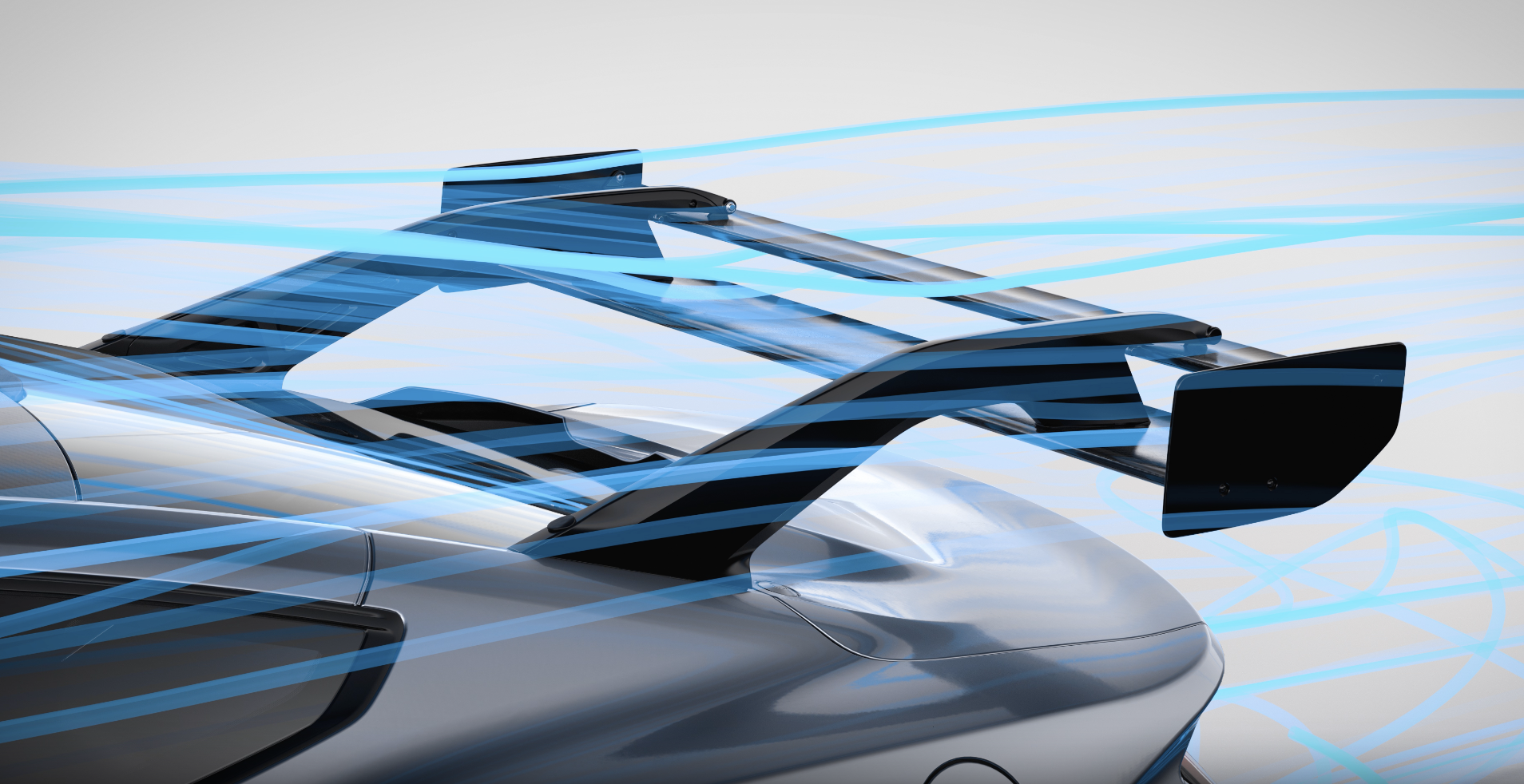

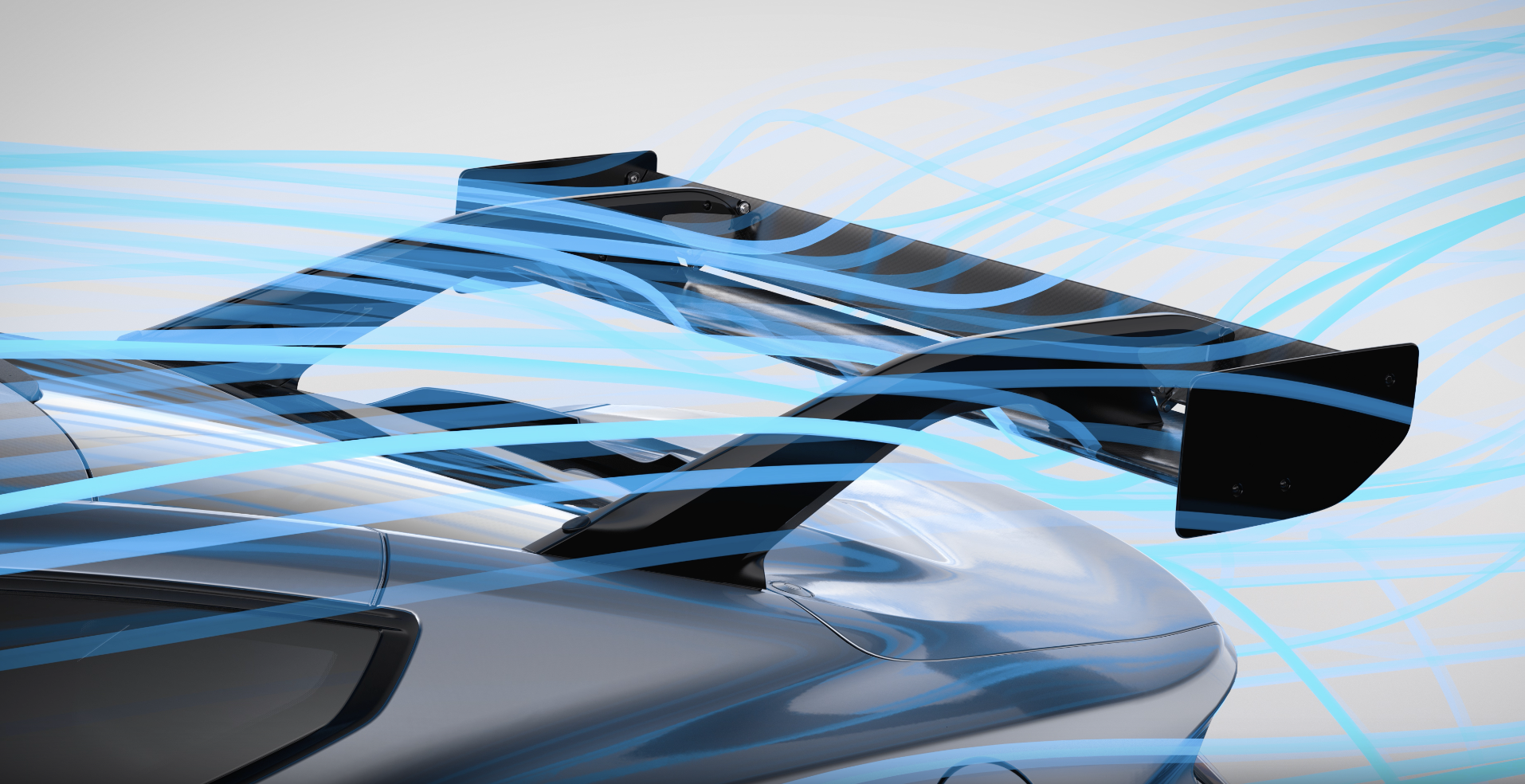

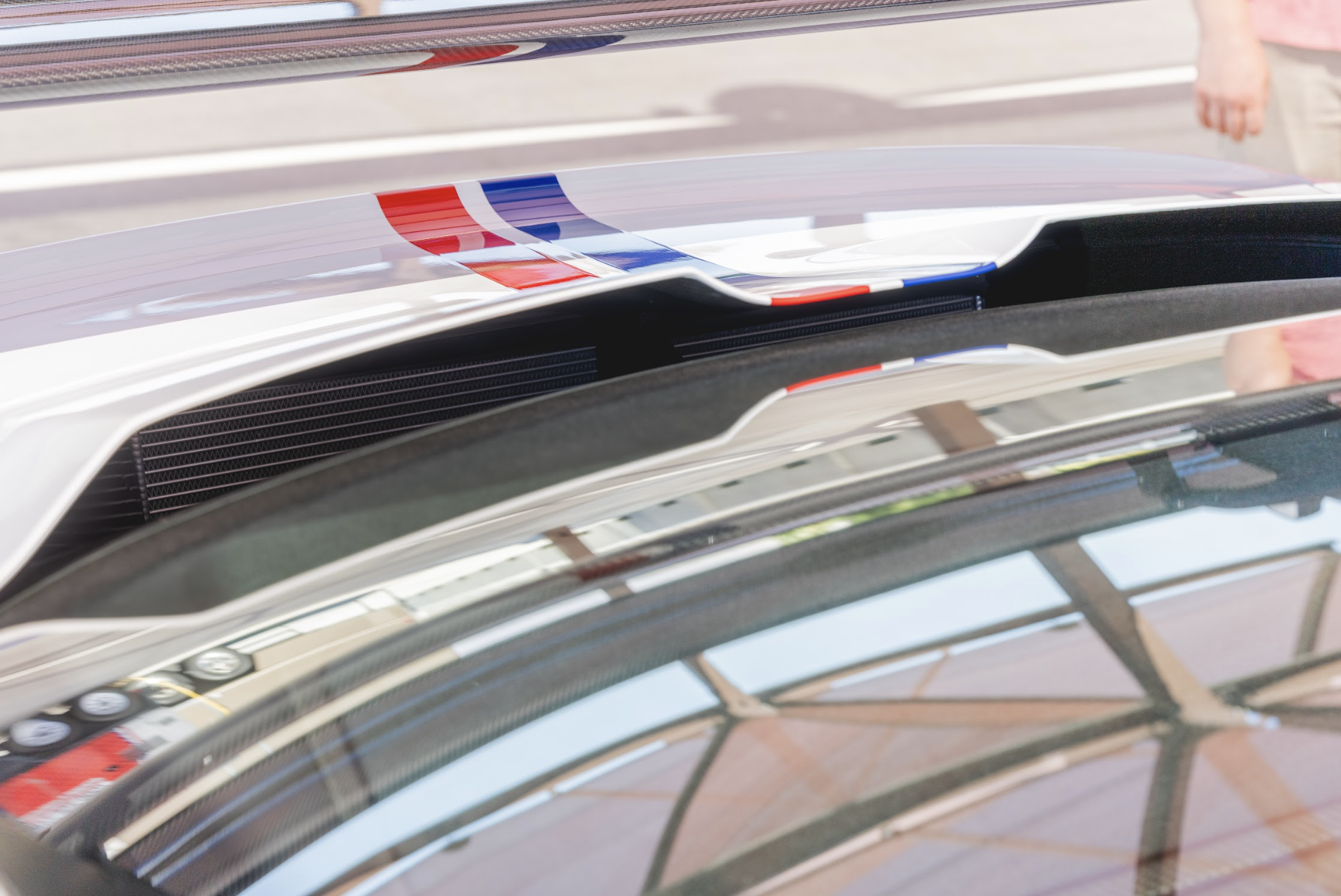

Still, there’s way too much good stuff to ignore. Check out that carbon fiber wing; it’s bolted to the hydroformed roof structure under the GTD’s carbon fiber rear quarter panels.

I actually managed to dig through some Ford footage to find a little bit of video footage showing the actuators in the wing; here’s a screenshot:

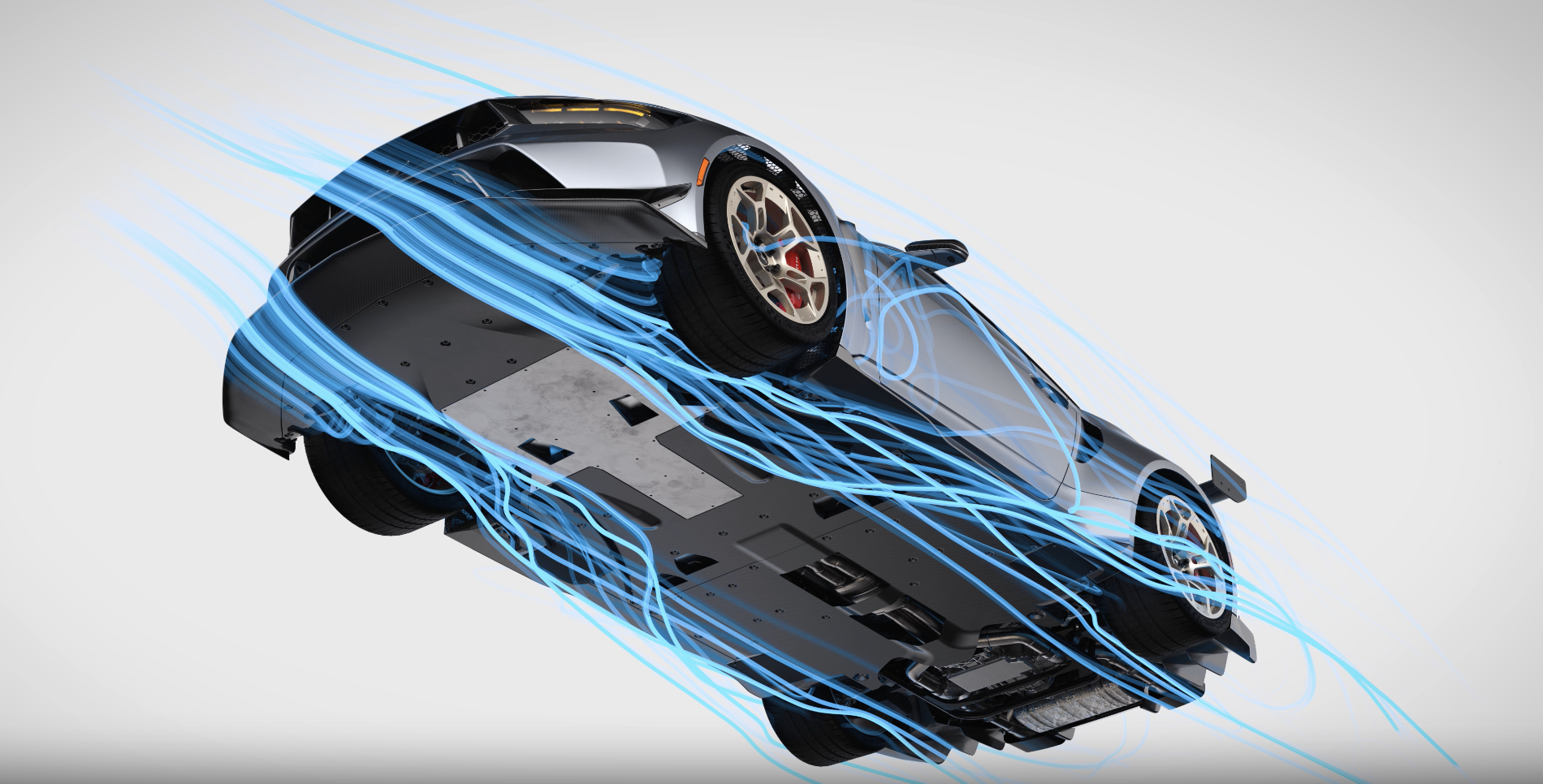

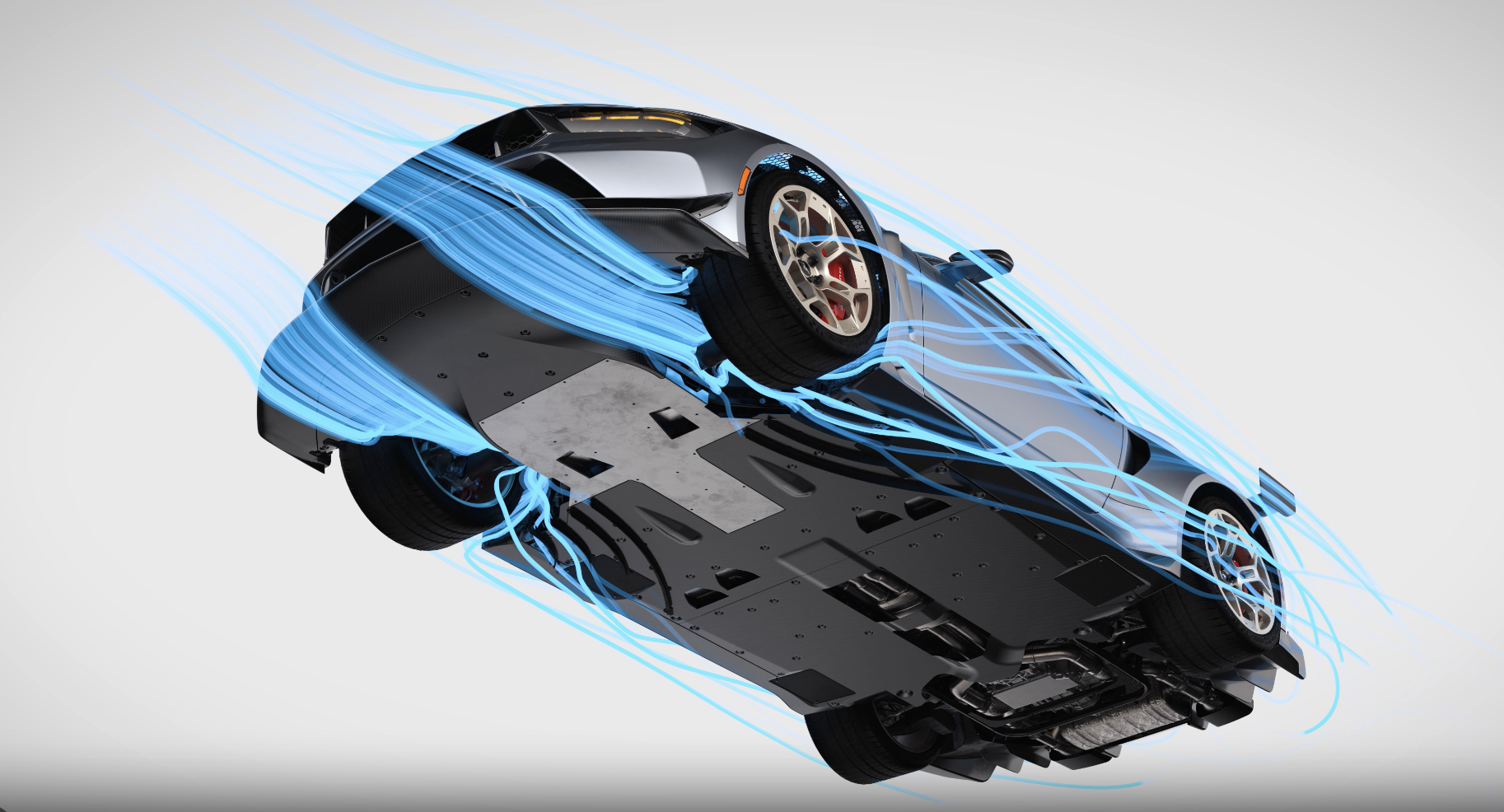

This is a hydraulically actuated rear wing that flips up to maximize downforce and down to maximize straight-line speed. The wing’s hydraulic system is directly coupled to front air deflectors that are really hard to see. Luckily, Ford put a GTD up on a hoist just for me!

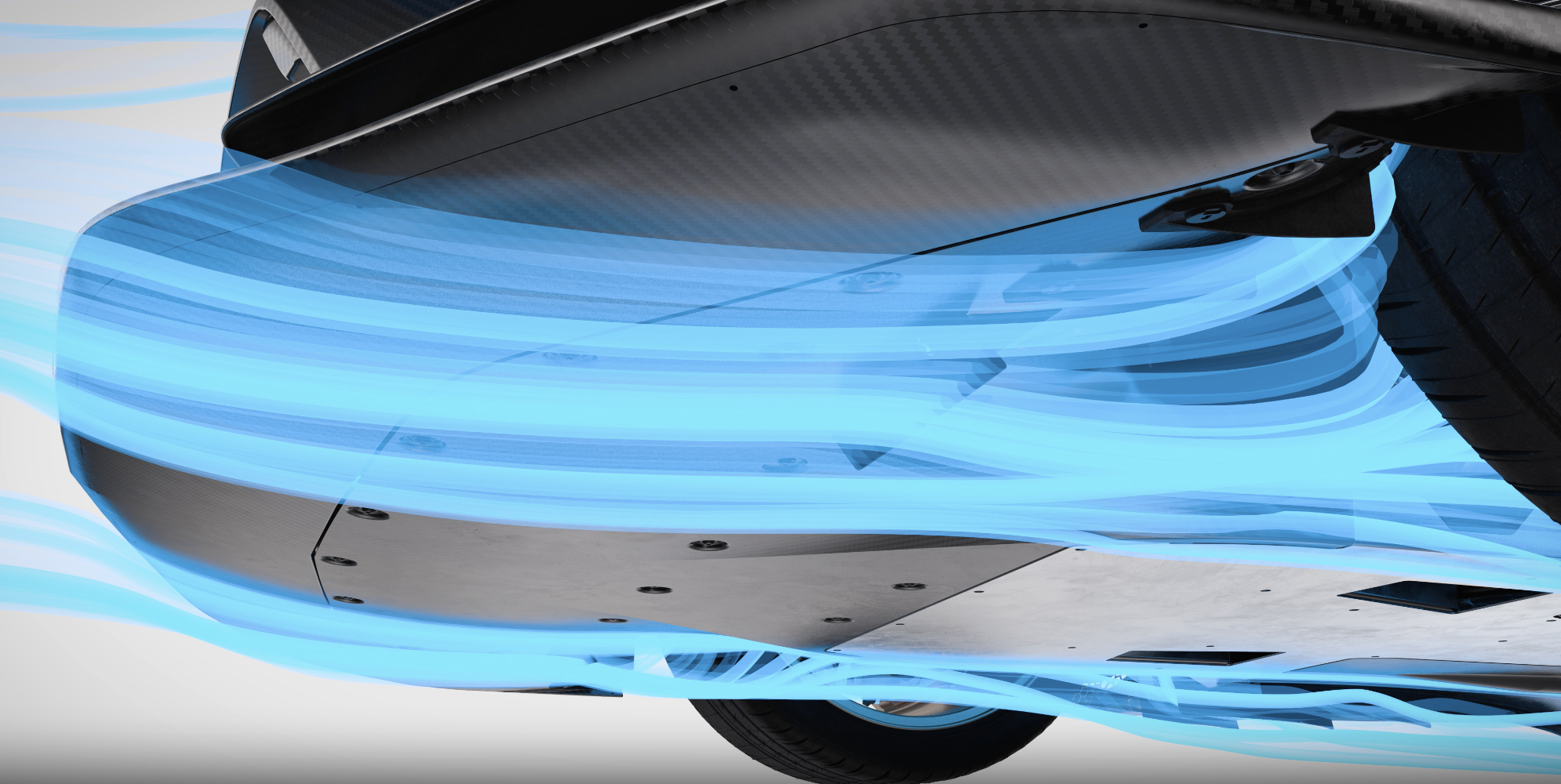

With the vehicle on the hoist, you could see the DRS (Drag Reduction System) Flaps just under the car’s chin, really nicely integrated into the underbody shield. “So this is where it gets a lot of its front downforce from,” Murray White from Multimatic told me. “When this is closed, the rear wing flap is always closed. So you got maximum downforce at the back…[and] front.”

“Whenever the rear wing flap is open in [Drag Reduction] mode, these flaps deploy into the airstream and stall the flow under the splitter, so it’s not creating as much front downforce to balance to balance out the rear downforce, which has dropped when it’s gone into DRS.”

It’s perhaps not intuitive, as deploying the flap actually decreases drag because it stalls airflow through parts of the front end that would otherwise turn that airflow into downforce and thus drag. Ford breaks it down:

The front underbody is shaped like a keel that helps evacuate incoming air through the front wheel wells and large fender louvers to create an area of lower pressure that acts like suction to help keep the front end stable through turns.

“We actively manage where the center of air pressure is on the vehicle, so the front and rear can remain balanced,” said Goodall. “The ability to do this isn’t allowed in racing, where the rules don’t allow actively managing airflow.”

The flaps work together with the rear wing, sharing a hydraulic system so that if one of them fails, they both go into maximum downforce (and thus drag) mode for safety. Here you can see the car in Low Downforce Mode, with the wing open and the flap down:

And here’s high downforce:

The flow in the high downforce mode appears more laminar up front (since it can feed the underbody downforce-enablers) but more turbulent out back at the wing. Here it is from the side going from low downforce:

To high downforce (see below); again, in low downforce mode, those front flaps are tripping up that air quite a bit as you can see above.

Here’s another angle going from top speed-mode to stick-to-the-road mode:

Here’s a different angle: Low downforce:

High downforce:

Low downforce:

High downforce:

Low downforce:

High downforce:

You get the idea.

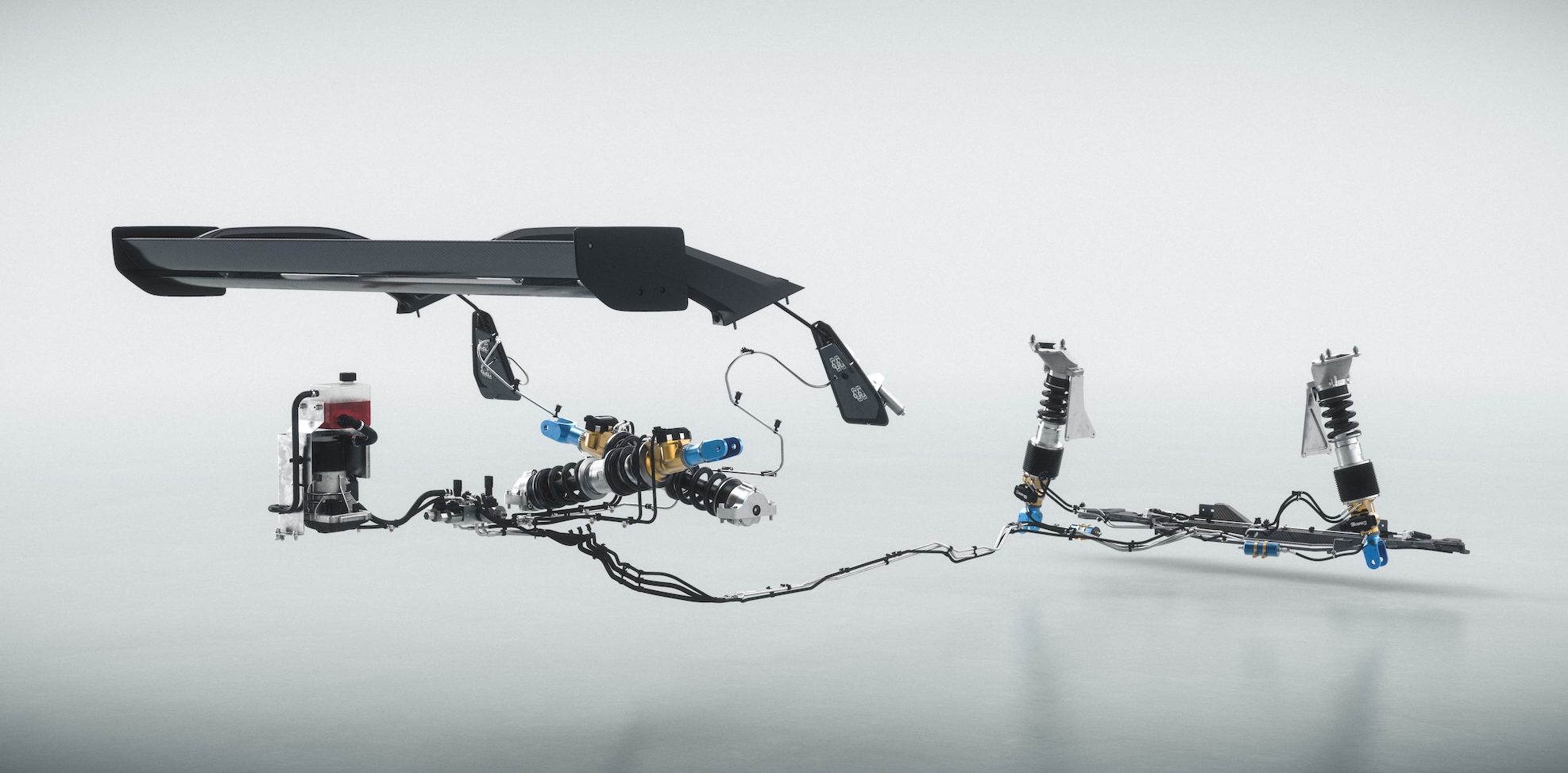

To finish off discussion about the hydraulic wing and flap, I’d like to show you Ford’s great images of the full hydraulic system, which links the four dampers/springs with the DRS flap and wing:

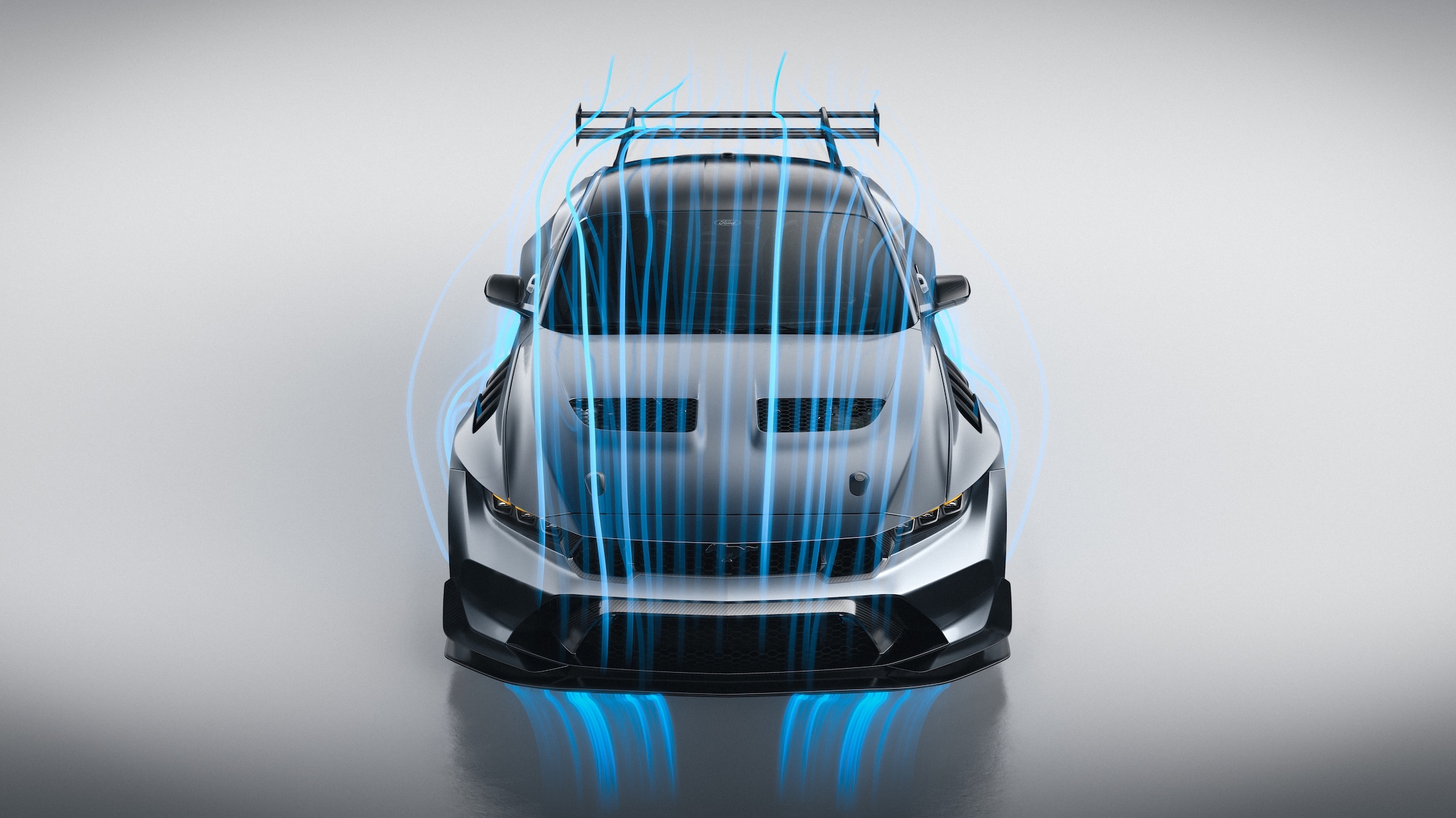

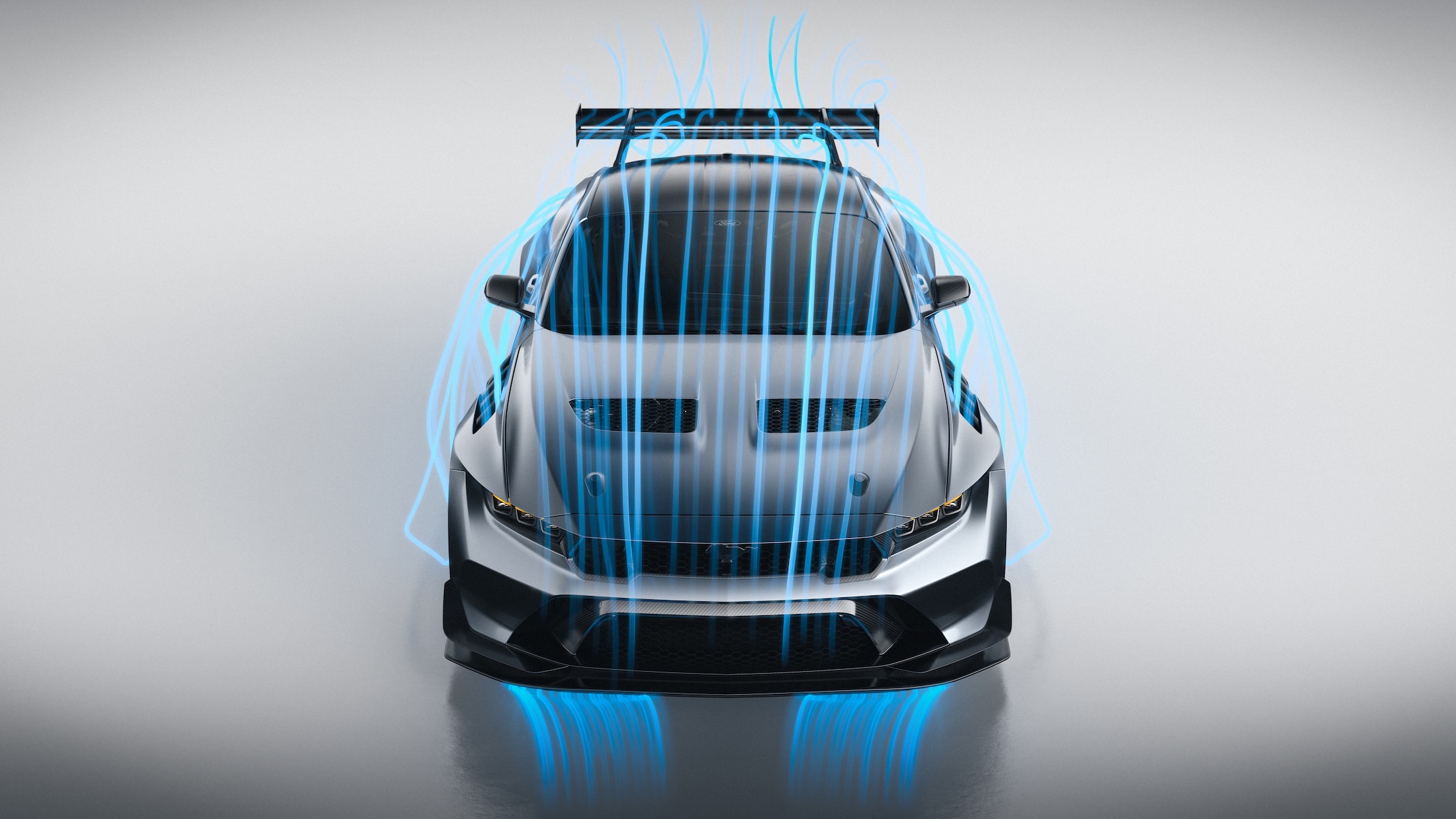

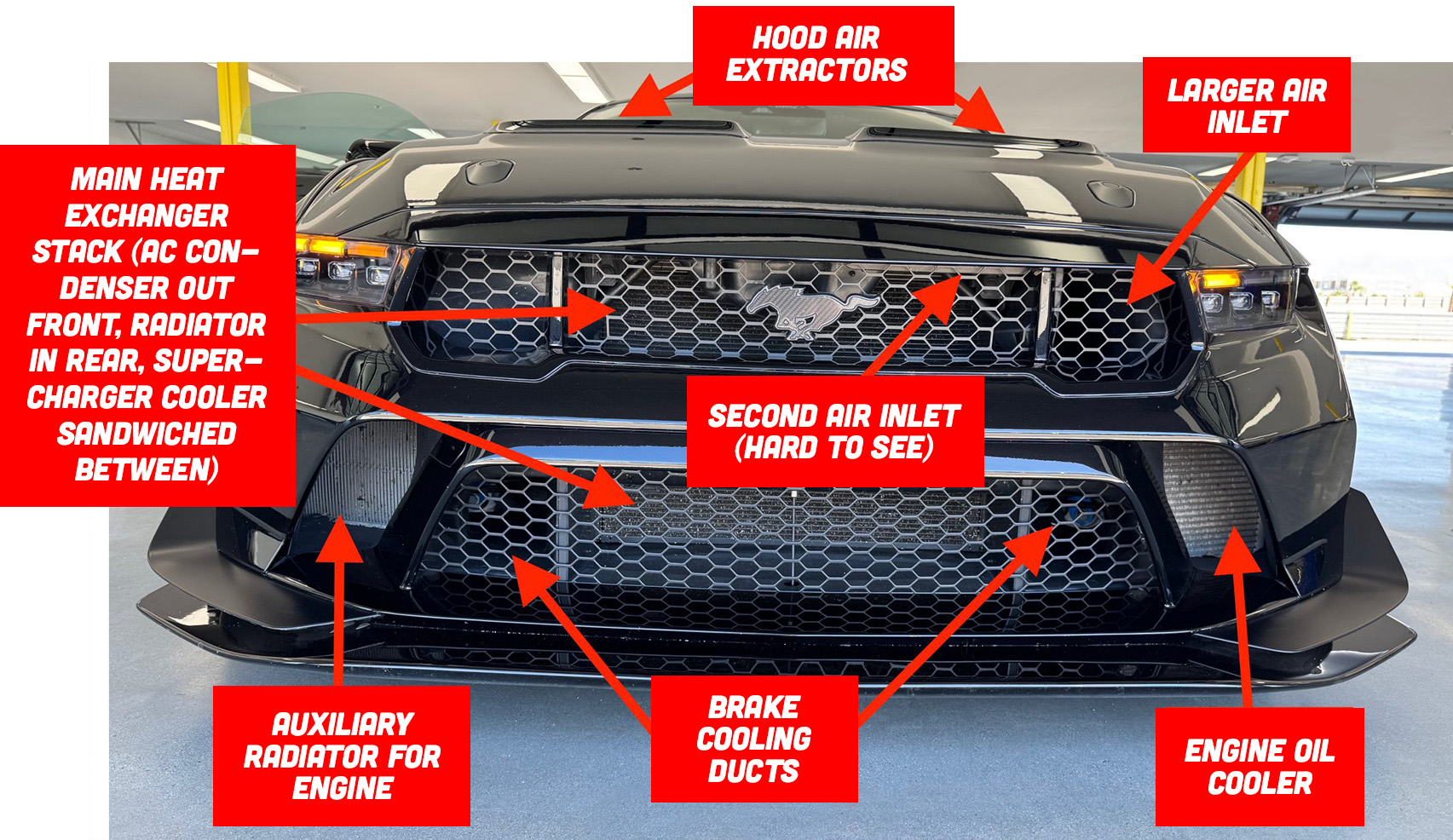

Of course, there’s so much more to the Mustang GTD’s aero than just the Drag Reduction System. Just look at this face:

The main cooling module out front consists of a standard radiator and an AC condenser, both sandwiching a low temperature radiator meant to cool the engine’s gigantic 2.65-liter Eaton supercharger. The outboard heat exchangers are an auxiliary radiator on the passenger’s side and an oil cooler on the driver’s side. Other inlets at the front include engine intake ducts and brake ducts, the latter of which I snagged a few photos of, because who doesn’t want to see the inside of some brake cooling ducts?

Note the clever plastic air deflectors sending air towards the brakes:

And here are the outboard heat exchangers up close exchanger, starting with the oil cooler:

Here’s the auxiliary high-temp radiator (engine radiator):

On the back side, here are the brake duct and outboard heat exchanger outlets in the fender wells — again, check out the air deflectors:

It’s also worth looking at the dual air intakes at the front of the car — intakes that Ford says were required to maximize power from the engine by reducing the intake system pressure drop. Here’s the main intake:

And up above you can see the secondary one:

Another notable aero/thermal element is the hood air extractors.

Part of me was a little disappointed Ford didn’t go with a ducted cooling module — the holy grail of cooling solutions because ducting air out through the hood allows for lots of airflow through the cooling module without all the “cooling drag” (and potential front-end lift) associated with air flowing into a rather un-aerodynamic engine bay.

The GTD’s mesh extractors above, though, are just extractors — they basically allow air from the high-pressure engine bay to flow out through the hood. The air coming out of the back of the heat exchangers isn’t exactly ducted cleanly — it just pressurizes the engine bay, and the difference in pressure between the pressurized engine bay and the low pressure, high-flow air above means air leaves through those extractors, reducing underhood heat and promoting cooling module airflow.

Todd Valentine made it clear that a ducted cooling module like those in a Mustang GT3 car would have been a major packaging nightmare, not to mention it would have required a major tear-up to the front of the car (the GOR, Grille Opening Reinforcement), which has crash/other regulatory implications.

Todd also showed me the front fender vents which help with air extraction and thus reduce lift, and he showed me the side vent, which he claims helps vent the cabin via the cabin exhausters (another rep told me they’re just aesthetics):

Todd also pointed out that, though GTD owners are not likely to regularly drive in downpours, the engine is designed to handle water coming through the hood’s extractor mesh. That fuse box on the left, and those two SMOG pumps mounted to the radiator support, both feature covers to protect them against the elements (see photo two above). Todd also pointed out the little flicks on the hood air extractors, saying they shift the center of pressure forward, and that their addition was a result of Nürburgring driver feedback, with the result being a front end with a bit more feel.

So many of the aerodynamic enablers are interconnected; the vehicle has to work as a system. Things like those hood flicks above, the roof, even the mirrors, could affect the rear wing’s ability to create the downforce needed to slay the Nürnburgring. The interconnectedness of it all is obvious when you look under the GTD, too. There, you’ll find Tire Wake Deflectors.

“They’re part of the underbody downforce package, so it deflects the air, affects the airflow around the car and underneath the car to improve the downforce, particularly in front of the car,” Murray told me:

Ahead of those Tire Wake Deflectors you’ll see some ducts for exhaust cooling. With that big flat carbon fiber/aluminum belly pan spanning the entire length of the car, the heat of that exhaust gets trapped, hence the need for these ducts and openings:

Aerodynamics is a balancing act, wherein you have to consider the airflow needs of various components — various cooling modules, the exhaust system, the brakes, and on and on. We’ve already had a look at the front brake ducts; here’s the rear. It’s a big plastic channel with a grate out front to keep stones out, and it Y’s off to send air to both the pads/caliper above and bottom of the brake rotor:

While I’m in this area, I’d like to point out that the fancy pushrod suspension’s pushrods that we saw all shiny earlier are in reality protected by a rubber bellow so that they don’t introduce dirt into the rear spring/damper area that you see through the clear window in the car:

In fact, let’s have a deeper look at that area behind the rear suspension window.

The Tech Panel

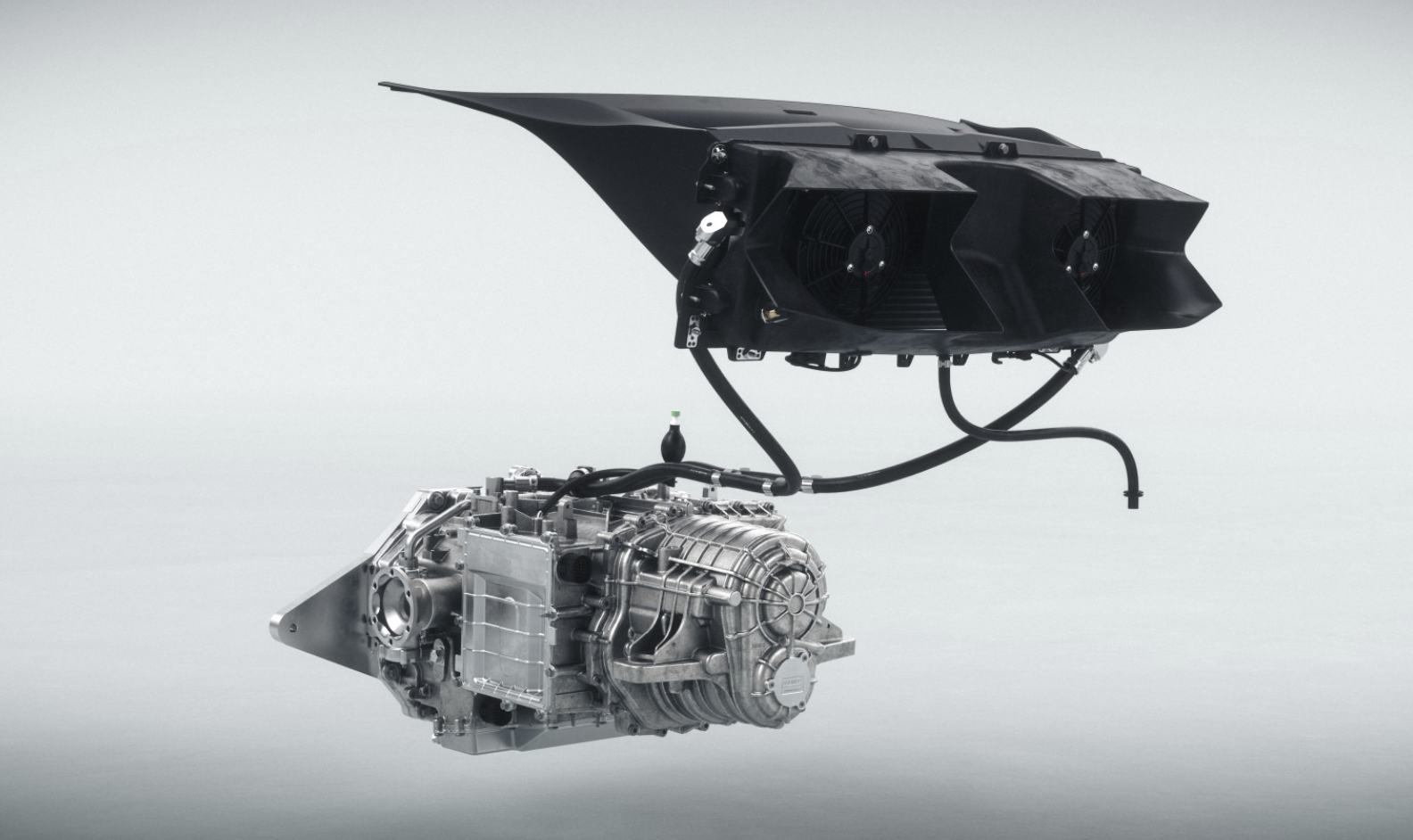

One of my favorite parts of the GTD is the “tech panel,” mostly because I like the name. It’s what replaces the standard car’s trunk lid, and is fastened to the car via some hood pins and one latch at the rear; the tech panel features an opening at its front to allow air to feed the transaxle cooler in the back.

This means the cooler is quite close to what it’s cooling, which is a good thing for effectiveness and weight-savings:

Anyway, here you can see the tech panel:

And here is a GTD with that removed:

That duct under the tech panel sends air through the transmission cooler, out the back of the car; you can see the dual fans behind the heat exchanger when you look at the rear of a GTD:

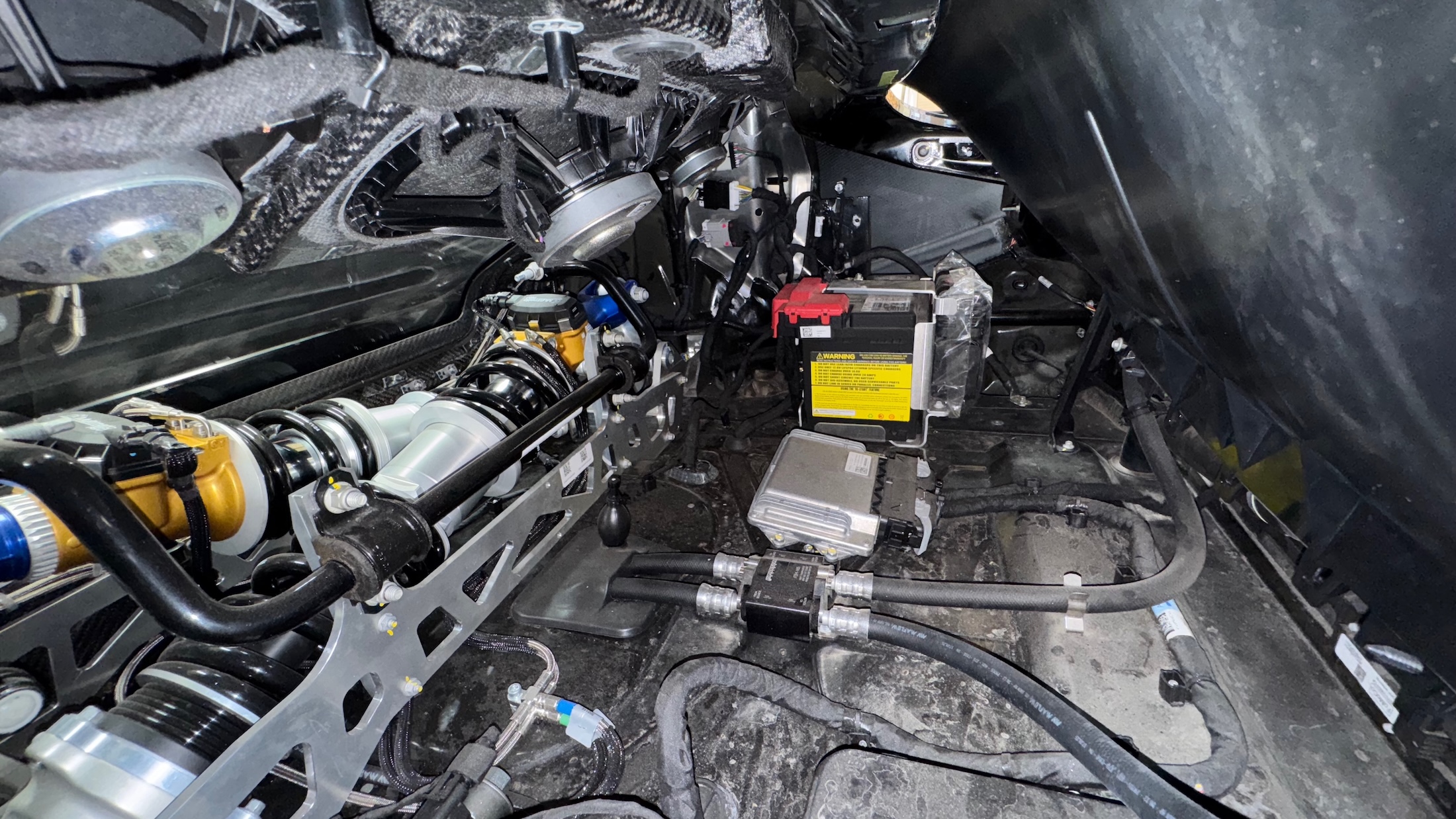

Let’s check out what’s under that tech panel — this area is not meant for storage, but there is space:

Here, let’s hit the light switch:

You can see that dual-layer aluminum floor that’s been glued into the massive hole Multimatic cut with a plasma cutter to fit the transaxle below, and on top of that new floor, bolted into the subframe below, is the gorgeous suspension that you see from the window inside the car. On the left side of the image above you can see the reservoir for the hydraulic system that feeds the suspension, rear wing, and front DRS flaps; that reservoir is packaged alongside the pump itself.

Above the spring/damper assembly, you can see some subwoofers built into a special carbon fiber cover that houses the see-through panel and that takes the place of a seatback on the non-GTD Mustang.

On the passenger’s side of this space under the tech panel is the battery, and between it and the hydraulic pump, on that new aluminum floor, you can see hydraulic hoses going through a rubber grommet.

It’s all a bit… untidy. But that’s why I started this article by saying the engineering of this car is a bit strange; “It was slightly unusual; we’ve done modifications to existing body-in-whites before, but I’d say this is the most extreme,” Murray White from Multimatic told me. And indeed. Hacking off quarter panels and a trunk floor with a plasma cutter, gluing in a new floor, and bolting on front suspension mounts to a crash rail does seem “extreme,” if a bit inelegant.

But What Is It Like To Drive?

My first drive in the Ford Mustang GTD was on an autocross track, and it was there that I experienced launch control, and the difference between Normal Mode and Track Mode. In track mode, which is activated when the vehicle is in park, the suspension drops about 40mm, and everything firms up. As Murray told me, the springs have to be rather stiff so that they don’t bottom out when hitting a small bump while the car is making its tremendous downforce (1355 pounds at 150 mph), and indeed, they totally change the demeanor of the car.

In normal mode, the car feels sharp enough, but in Track Mode, it feels glued to the ground. I didn’t spend a ton of time autocrossing the GTD; all I could gather was that the steering felt well assisted, though getting the big car through those cones did require me to really hack away at that wheel. I also found that the launch control system seemed to short-shift first gear in a rather jerky fashion.

The day after autocross, though, I hit the track and the GTD came alive. The car, per the handbook, was track-prepped by adding a degree of negative camber (see image below on how to adjust the suspension) and removing the mesh hood vents to aid with both front downforce and cooling — just rips.

Sure, the GTD is 4,400, but if there are three things that can hide over two tons of curb weight, it’s an 815 pound motor, a literal ton of downforce (at 180 mph), and rolling pins for tires. I’m far from a racecar driver, but I hammered the throttle and sent the GTD through sweepers at speeds that could have separated cream from milk. I mashed on the brake pedal and squeezed those six-piston Brembo calipers hard against those 16.5-inch front pizzas, with those 325mm front tires scrubbing off speed and the nose darting into the turn confidently as I leaned onto the throttle on the way out and listened to 5.2-liters of supercharged V8 fury roar across the desert.

If there’s one term I can use to describe how the Mustang GTD drives, it’s “easy.” I turned traction control completely off, and I still hooned the beast around the track without getting killed, it really wasn’t too long ago that, had I told you about a 4,400 pound 815 horsepower car, you’d likely have replied with: “Sounds like a deathtrap.” The GTD is anything but. Its combination of downforce, huge tires, a massive track width, an absurd engine, a transmission that shifts truly perfectly and is always in the right gear when you want it to be, and some on-board traction control trickery yields one of the most approachable high-horsepower cars I could ever have imaged.

You can absolutely romp on the GTD, and — at least in my case — the car’s capabilities were so far beyond my skills that I really felt comfortable giving it what at least to me felt like the beans. It was hilariously fun, with my only real complaint being that my seat was clicking all over the place. I don’t know if a bolt was loose or if there was just slop in the mechanism, but relative motion between your butt and a car is not the best way to feel “at one” with a machine.

On road, it was the same story: Easy. Sure, there was some road noise, and there was a bit of bumpiness, but in normal mode, one could daily drive a GTD with very few complaints other than what I’m sure would be single-digit fuel economy.

There are some practical concerns with daily-driving a GTD, of course. There’s no trunk, so you have to throw all your junk behind the front seats near the clear suspension observation window:

And then there’s the interior, which will be every journalist’s complaint. A $330,000 car with essentially the same interior as a regular Mustang that costs 20 percent of the price?!

It’s a valid complaint, but it’s again another example of where the insistence of this car being a Mustang comes with compromises. Personally, I’m fine with the interior other than the rotary dial shifter, which I contend belongs in a minivan and not a supercar.

Ford Achieved Its Goal. The Result Is A Ridiculous Halo Car

We return to the criticisms I mentioned at the top of the piece: 1. The GTD is too much of a Mustang for its price and 2. The GTD isn’t a Mustang.

Neither is wrong. For $330,000, maybe you could ask for a car that doesn’t share much of an interior with a car 20% its price. Maybe you could ask for a seat that doesn’t rattle around (Ford says this was a Pre-Production unit). Maybe you don’t want to have to deal with the compromises associated with trying to adapt an existing body into supercar-status. Maybe the idea of plasma-cutting quarter panels and trunk floors feels a bit too primitive for you. Maybe this doesn’t look like supercar material:

But while the above may not look like it belongs in a supercar, it does belong in a racecar, and that’s what Ford was going for here — a racecar for the road. Still, the complaints are valid.

So is the second point about this not being a Mustang. While I personally think it is a Mustang given how it’s built, and that its Mustangness led to a bunch of compromises that competitors haven’t had to deal, you could make the argument that once you’ve bolted in an entirely new pushrod rear suspension and replaced the front MacPherson strut setup for a multilink design — all at considerable cost — what you have is no longer a Mustang. Yes, Ford technically has adapted the S550 platform to show the art of the possible with those bones, but with all the chopping up of the body, all the bolt-on adapters, and the crazy high price, have you really proven what your engineers can do with the Mustang platform or have you just shown that you can pay Multimatic enough money plasma-cut your car into something that can handle well?

There are lots of ways to spin the Ford Mustang GTD, but here’s my view: It is awesome.

Yes, it’s in some ways not the most elegant design, and it does definitely feel more racecar-y than supercar-y. But nobody asked Ford for the Mustang GTD. It’s not going to make the company a ton of money. It’s a preposterous, totally unnecessary exercise trying to adapt the S550 platform into a competitive supercar, and doing so was clearly a tall task given all the slicing and dicing and the heavy MSRP, but that’s exactly the kind of thing I love. Just going out and doing something ridiculous just because.

Whatever side of the “is it too Mustang or is it not enough Mustang” argument you’re on, one thing I can promise you: When you see a Mustang GTD in person, it’s going to stop you in your tracks.

I myself wasn’t sure it would do this; I thought folks would see “just another Mustang.” But I couldn’t have been more wrong. The Mustang GTD draws in everyone like a magnet. Even people with just a passing interest in cars know it’s something special, and can’t help but ask questions.

Ford’s goal was to do a sub 7-minute Nürburgring lap, to create a technical showcase for the Mustang brand, and to create a halo car. I’m not saying the car is perfect, but if that was the goal, Ford pulled it off.

All Images: Ford Motor Company or David Tracy or Griffin Riley