Pam Melroy, one of only two women to ever command a NASA space shuttle, is channeling her decades of experience across the U.S. Air Force, DARPA, the FAA and private industry to pioneer a revolutionary new rocket engine technology.

Melroy, NASA’s former Deputy Administrator, has joined the Board of Directors for Houston-based startup Venus Aerospace just months after the company became first in the U.S. to launch a rotating detonation rocket engine (RDRE).

A Sept. 2 announcement of Melroy’s appointment to Venus’ board comes as the company now prepares for a major expansion. Company CEO Sassie Duggleby said bringing Melroy onboard was an easy decision. “Her career has run the gamut of all the areas that we’re trying to hit. Once we got introduced to Pam, it was an absolute no-brainer,” she told Space.com in an interview.

Melroy is a bona fide spaceflight expert, and Duggleby said Melroy’s background matches the exact markets Venus hopes to disrupt: civil, defense, and commercial aerospace.

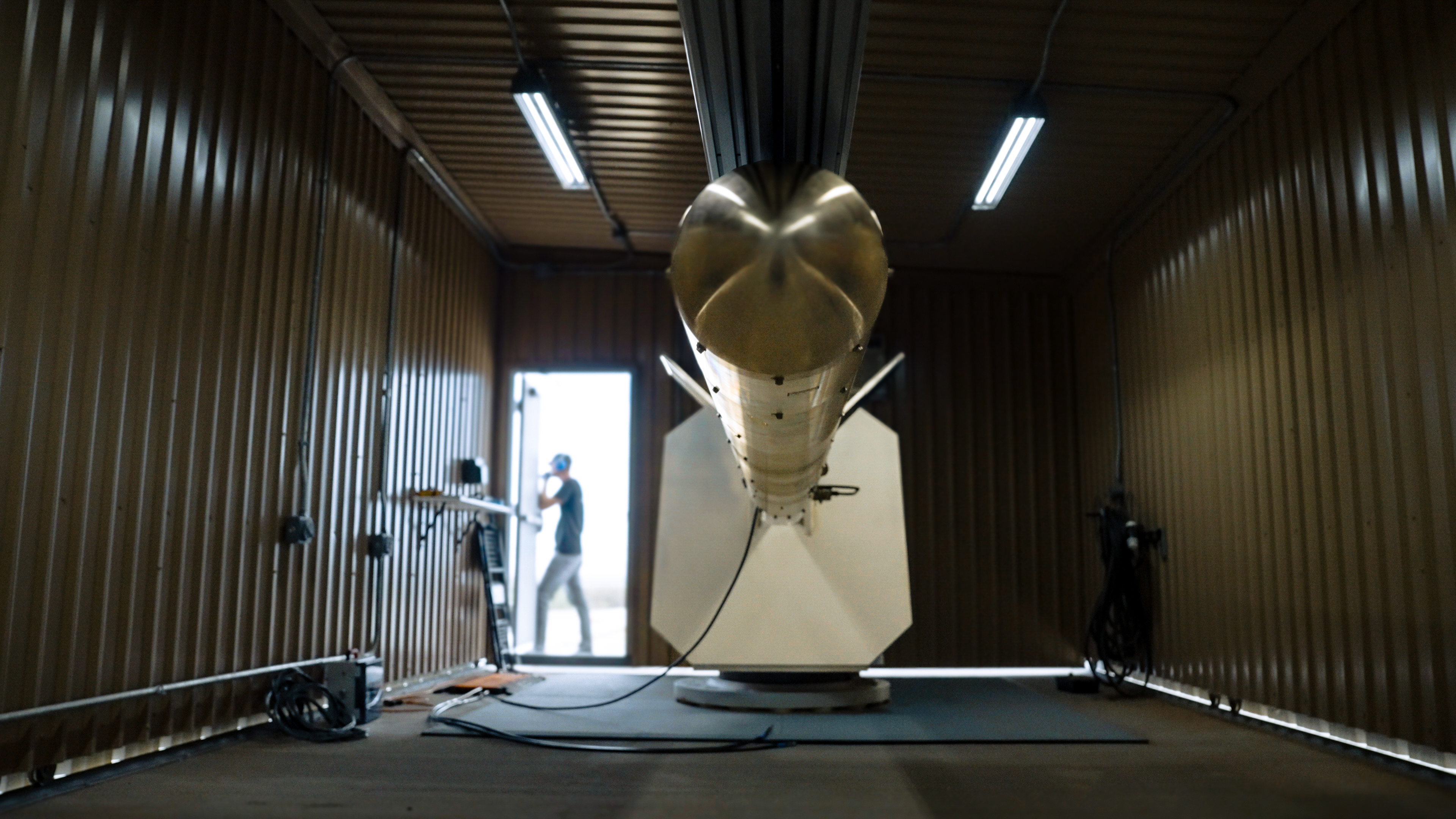

The company’s suborbital liftoff on May 14 demonstrated that the RDRE, a propulsion technology that existed only in theory for more than half a century, could operate under real flight conditions rather than just on a test stand. Venus’ RDRE launch set off a wave of industry-wide attention, according to Duggleby, which led the company to add Melroy’s veteran spaceflight expertise to their ranks.

“Since our flight, the amount of interest for Venus has been almost overwhelming,” Duggleby said.

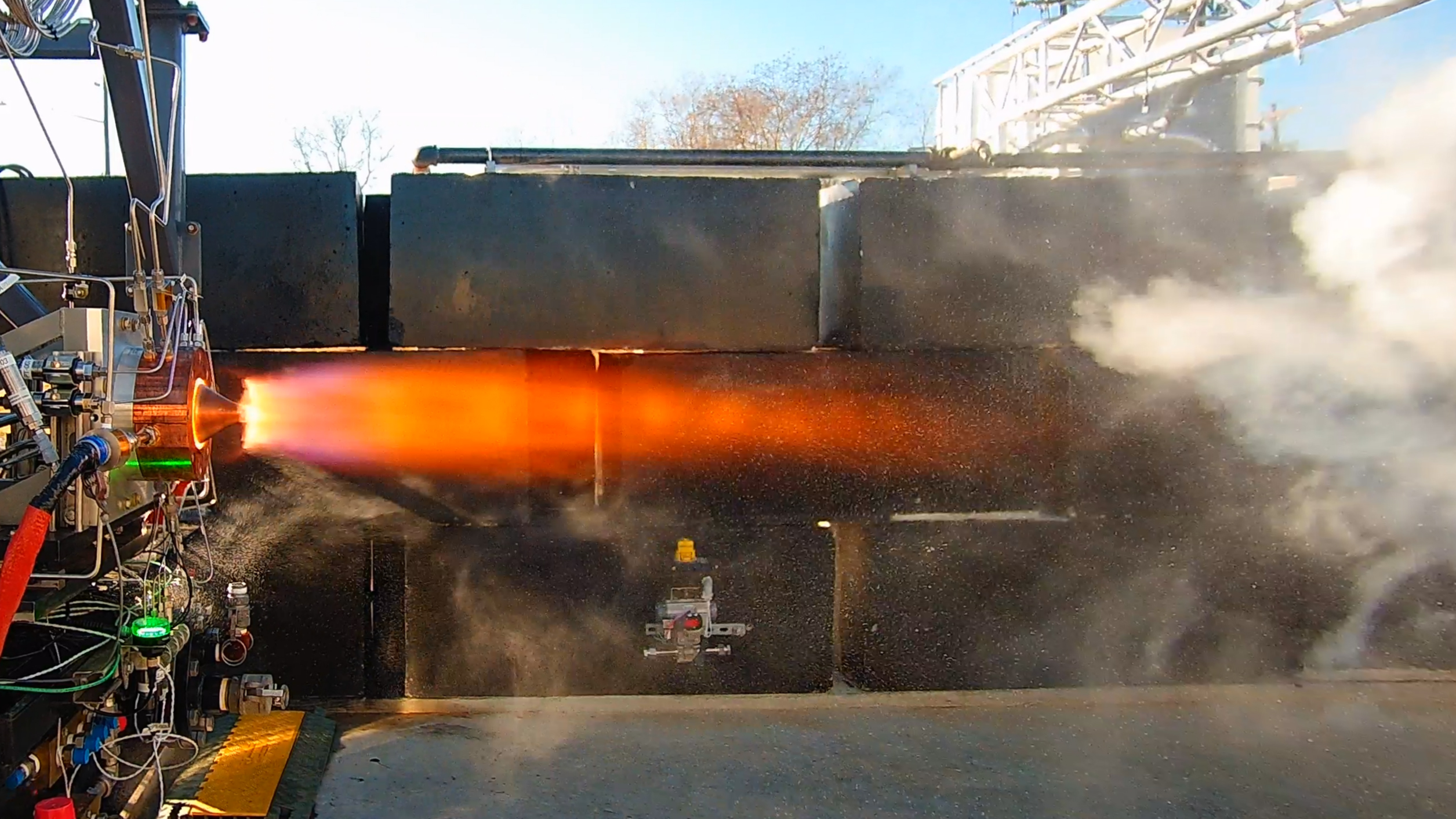

The result was a credibility shift. “We had a customer who told us, ‘We thought you guys were a PowerPoint presentation,'” Duggleby said. “When we showed them a 40-second engine test, they said, ‘Oh my gosh, it works!'”

What is the RDRE?

Melroy told Space.com that she first encountered the idea of RDREs a decade ago while at DARPA, when a breakthrough always seemed just out of reach. “It was one of those technologies that has always seemed elusive,” Melroy said, adding that “it was the classic joke: ‘it’s always about 10 years away.'”

What sets the RDRE aside from your everyday rocket engine is the way fuel ignites inside the combustion chamber. Conventional engines burn fuel in a steady process, where the flame front (the area at which combustion occurs) moves smoothly through a propellant mixture to produce continuous thrust. RDREs use a detonation wave that races around a circular channel, which produces short, high-pressure bursts that drive up thrust and efficiency. So, instead of a smooth output of flame, the engine runs on a continuous series of controlled explosions.

The concept has been studied since the 1950s, but engineers struggled to stabilize the detonation long enough for flight. “Most rocket engines flying today are based on 1960s and 1970s technology,” Melroy said. “The efficiency jump of RDREs is really a game changer for launch and for other applications.”

Venus claims their RDRE technology offers a 15% increase in efficiency versus conventional rockets, enough to nearly quadruple payload capacity when compared to legacy engines, according to Duggleby.

The technology a joke no longer, Melroy said, “They’ve done it. We’re there … That’s why Venus is getting so much interest.”

How did Venus Aerospace do it?

The decades-old technological riddle was finally solved thanks to three major advances, according to Duggleby.

First, 3D metal printing allowed Venus to innovate quickly, by creating an environment where the company could learn from its failures and make fast changes. Duggleby said their innovative speed was increased further by the decision she and her spouse, Andrew Duggleby — Venus co-founder and CTO — made to move the company from Southern California to the Houston Spaceport.

“We design, manufacture and test all in one single location within 100 yards of each other,” she said. “That has allowed us to innovate quickly.” Duggleby said Venus’ current record stands at eight engine tests in a day, and 28 engine tests in a week. Over the last five years, she said, has made Venus’ program, “as far as we know, the fastest new engine development in history.”

The second component making Venus’ RDRE breakthrough possible was a high-speed camera. According to Duggleby, Venus engineers used a camera shooting at 1 million frames per second to slow down the RDRE ignition process and observe the engine’s detonation sequence in as much detail as possible. “Trying to understand how you can get sustained detonation has been key,” Duggleby explained.

The third breakthrough is for aspiring RDRE competitors to find out for themselves. “I’m going to hold on what the third one is, because I don’t know that I want it public,” Duggleby said, but added, “there was one more innovation that we used.”

After proving their concept works with the successful test launch in May, Venus is now focusing on applications for the new engine technology.

“The engine is proven. It’s ready to go,” Duggleby said. “There aren’t more milestones that we need to go hit to start doing some integration with our existing customers.”

The company is now working to integrate the RDRE into real-world systems for buyers in the defense, civil and commercial space industries — Melroy’s specialty. “All three areas are areas that I’m familiar with,” she said. “So, ideally, I can help [Venus] as they scale. I think this is a pivotal time for them, so I’m going to make myself very much available.”

Melroy said propulsion integration will be the main challenge ahead, but that May’s test shows that Venus knows the path: “It’s just a matter of getting the right size, scale, and then the integration to go on.”

San Francisco to Tokyo in two hours?

Venus sees a range of applications for its RDRE as diverse as its customer base. Duggleby said Venus’ “North Star,” one of its most lofty goals, is high-speed global travel, asking, “How does the world change if you can get from San Francisco to Tokyo in two hours?”

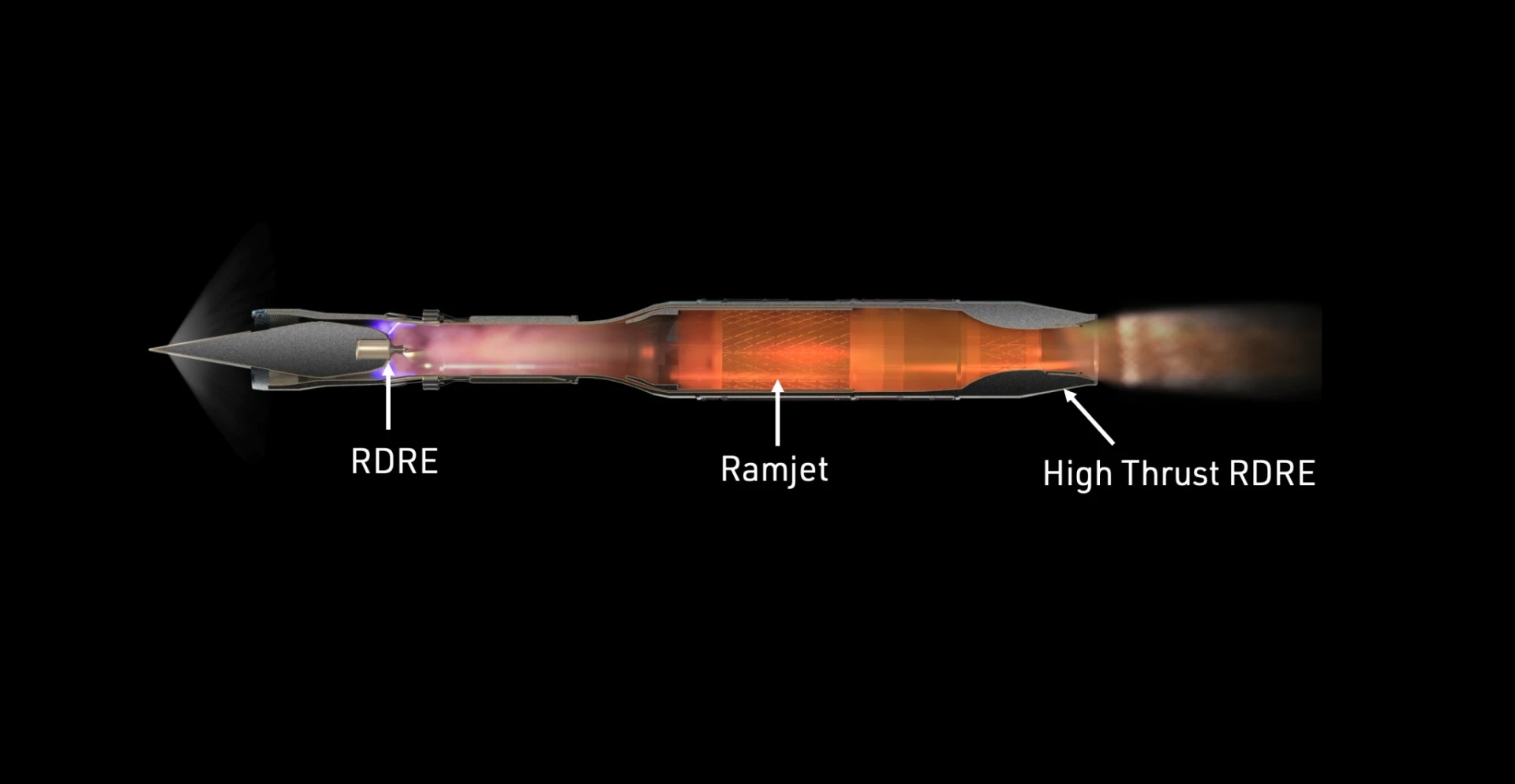

Focused on that North Star, one of Venus’ long-term goals is the Stargazer M4, a Mach 4 passenger jet designed for record fast point-to-point global travel. Its design pairs the RDRE with the Venus Detonation Ramjet (VDR), an air-breathing engine built for sustained hypersonic flight.

The trajectory puts Venus in a different category than most of its perceivable peers. Over the past decade, several rocket startups have struggled to move beyond prototypes, while a handful have managed to scale into reliable launch providers. Venus, by contrast, is focused on propulsion rather than whole launch vehicles, and has already achieved a technical milestone that no competitor can yet claim. “We flew the first ever high-thrust RDRE,” Duggleby said. “I don’t know that there’s an actual comparison right now.”

Duggleby envisions different versions of Venus’ engines flying low in Earth’s atmosphere, or all the way into deep space. “We believe in a future where this is the engine powering everything from launch vehicles to orbital transfer vehicles to landers,” Duggleby said. “There’s also,” she added, “near term applications for munitions.” That would be the “defense” portion of Venus’ industry-changing holy trio.

Launch and orbital transfer vehicles that can push vessels into deep space are RDRE applications where efficiency could directly cut costs and boost capacity.

“One of the things we really learned from the International Space Station is how much logistics people and their science need,” Melroy said. “I think we’re going to be seeing a lot more orbital transfer vehicles. You can see that’s becoming a big thing in Earth orbit, but I think it’s going to be a very logical outcome of [sending] cargo to the cislunar environment,” she said.

Melroy also pointed to landers as another application.

RDREs on the moon and Mars

NASA’s Artemis program is the agency’s first endeavor to land astronauts on the moon since Apollo. The program’s current architecture utilizes SpaceX’s Starship as the lunar lander for Artemis 3, slated for sometime in 2027. SpaceX is making progress with the vehicle’s development following a successful test launch in August, but still has a number of technological milestones to complete before NASA clears the spacecraft to land crews on the moon.

Starship’s powerful Raptor engines are fueled by liquid oxygen and liquid methane — both of which require cryogenic cooling to maintain their liquid states, and will need to be transferred between vehicles for refueling in order to reach any destination beyond low Earth orbit (LEO). Additionally, even with proper temperature regulation, both propellants will experience supply losses due to boil-off. SpaceX has yet to demonstrate a solution to either, whereas RDREs don’t need cryogenic propellants or, as Melroy noted, large engine bells at their base, making them well-suited for moon and Mars operations.

Melroy added that propulsion breakthroughs like the RDRE are going to set the pace for global space competition.

“China is watching. Others are watching,” she said. “They’re trying to build their own commercial space industry … Protecting our lead with this very innovative propulsion technology will have a huge economic impact for the United States.”

She argued RDREs could “supercharge the growth of the space industry.”

For Venus, that sentiment is fueling interest from across the sector — pushing the startup to scale quickly. Duggleby didn’t provide specifics about interested parties, but said “the customer pull that we’re getting is incredible.”

Melroy agreed. “Venus isn’t going to be small for long.”

Source link